Chemical resistant hoses are commonly used to transport chemicals, solvents and corrosive liquids in highly corrosive environments. PTFE, FEP and PFA are all common fluorinated polymer materials. They have the following differences in chemical resistance.

Chemical properties

PTFE: It is the most common fluorinated polymer. It has excellent chemical resistance, inert chemical properties, hardly reacts with any substances, and has high temperature resistance.

FEP: Compared with PTFE, FEP’s chemical inertness is slightly reduced, but it still has good chemical corrosion resistance and is a material with good heat resistance.

PFA: It is similar to FEP in chemical properties, but PFA has higher temperature resistance and heat resistance and can withstand higher operating temperatures.

Melt processability

PTFE: Due to the very high melting temperature of PTFE, its melt processability is poor. And it is usually processed by methods such as pressing and sintering.

FEP: FEP has a lower melting temperature and is easier to process into various shapes than PTFE, such as extrusion and injection molding.

PFA: PFA also has a relatively low melting temperature, making it easier to manufacture parts through processing methods such as extrusion and injection molding.

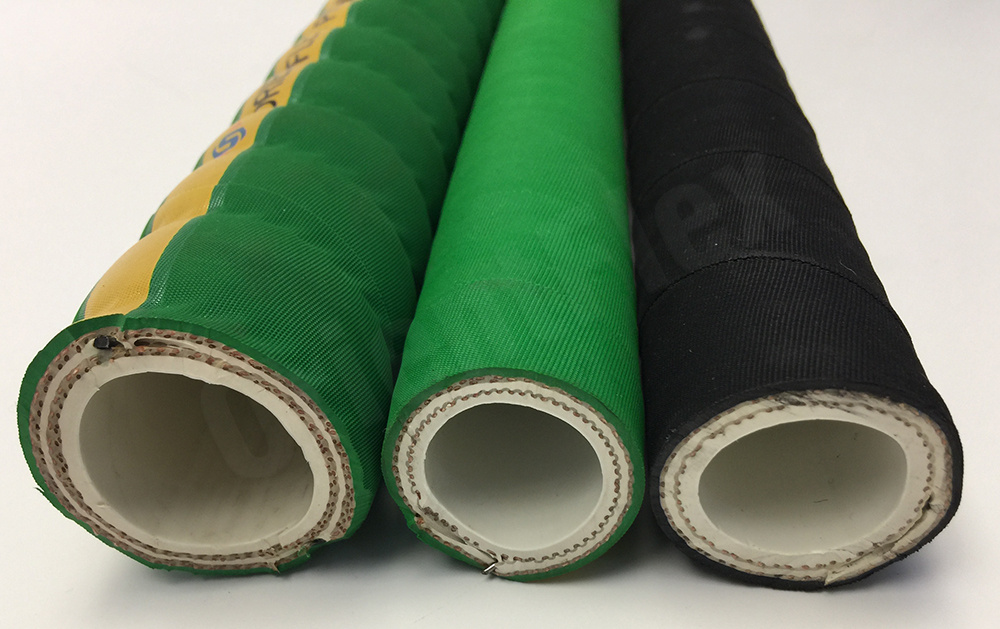

Transparency

PTFE: PTFE is opaque and generally white.

FEP and PFA: Both FEP and PFA are transparent, allowing observation of their internal structure and fluid state.

Application areas

PTFE: widely used in the manufacturing of seals, pipes, valves, bearings, cable insulation and other fields. It is also ideal for non-stick surface coatings.

FEP: Commonly used in manufacturing coatings, pipes, cable insulation, extrusion molding and injection molding applications.

PFA: Due to its high temperature resistance and chemical resistance, PFA is widely used in semiconductor, chemical industry, medical devices, aerospace and other fields.