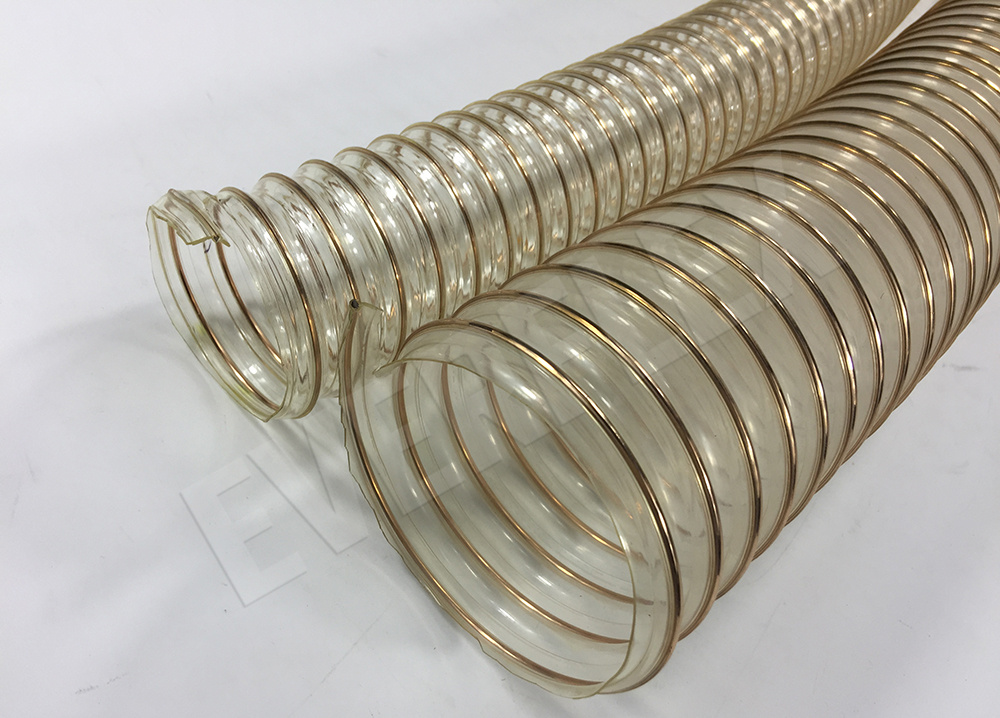

To answer this question, we need to consider the practical use of anti – static hose pipes. These hoses are crafted from PU, and as a result, they excel at absorbing static electricity generated by friction. This makes them one of the most effective ways to prevent static from the very source. In numerous industrial fields that involve suction operations, anti – static hoses are a must – have. Why? Because they not only boost work efficiency but also positively impact production, especially when it comes to maintaining hygiene standards.

Exceptional Properties of Anti – Static Hose Pipes

Anti – static hose pipes boast excellent resistance to chemicals, UV rays, and ozone. Thanks to their flexibility, they bend easily without the risk of leakage. Whether handling liquids or solids, these hoses perform admirably, which expands their application scope significantly. Temperature is no challenge either. They can operate smoothly within the range of -20℃ to 90℃ and can even withstand 120℃ for short periods. Moreover, they remain functional in cold winter conditions, avoiding excessive brittleness.

How to Select the Right Dust Extraction Hose

First and foremost, focus on the raw materials. The market is filled with hundreds of suppliers, but only a handful use top – quality materials. Inferior raw materials can severely undermine the hose’s performance. Typically, well – known brands prioritize high – grade raw materials in their production. Take Everflex, for example.

Secondly, brand matters when choosing anti – static hoses. Currently, only renowned suppliers can consistently deliver high – quality products. Such brands offer greater security in terms of both quality and technology. Additionally, famous manufacturers conduct strict inspections on their products. Everflex stands out as a reliable and well – established brand. Since its inception, the company has been dedicated to quality and service. It goes the extra mile to provide cost – effective hoses, making it an ideal choice for your needs.