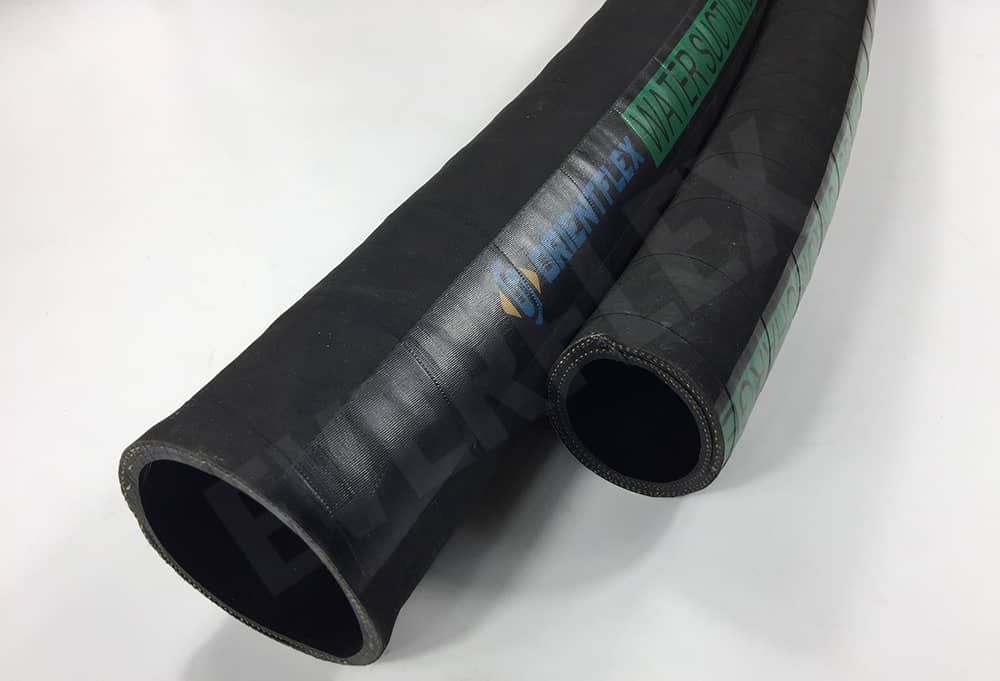

Rubber hoses offer a temperature range similar to thermoplastic hoses. Additionally, they are crush-resistant, meaning they won’t sustain permanent damage from impacts. Moreover, they require no special equipment for assembly. Flexible rubber hoses can even be manufactured in large sizes, such as 6’’ and 10’’, enabling highly efficient fluid transfer.

However, rubber hoses are best suited for low-pressure applications and are prone to corrosion. Fortunately, advancements in rubber technology have introduced various synthetic options. For example, nitrile rubber excels in oil resistance, making it a top choice for oil and fuel hoses. EPDM rubber, meanwhile, offers exceptional temperature and aging resistance, ideal for high-pressure steam hoses.

Industrial Hose Inner Wall Structure

Before selecting an industrial hose’s inner tube material, understand its wall structure. Determine whether the inner tube is smooth or corrugated, as this affects flexibility—corrugated walls bend like a straw, while smooth walls offer different advantages. Your project’s pressure, flow, and discharge requirements will guide this decision.

Smooth Inner Tube

A smooth inner tube minimizes fluid resistance, ensuring high transfer efficiency. Nearly all flexible industrial hoses can be designed with smooth inner tubes for optimal flow.

Corrugated Inner Tube

Compared to smooth hoses, corrugated rubber hoses offer superior bendability. And this makes them ideal for tight spaces. Besides, this design enhances flexibility, allowing easier maneuvering in confined areas.