Nylon tubes, also known as PA tubes or nylon hoses, are indispensable in modern industry due to their exceptional properties. Let’s explore their features, applications, and why Everflex is your go-to supplier.

Key Features of Nylon Tubes

Wear Resistance:

Nylon withstands harsh environments with sand, gravel, or iron filings, making it ideal for rugged applications.

Smooth Surface

Its low-friction interior reduces flow resistance and prevents rust or scale buildup, ensuring long-term performance.

Flexibility & Rigidity

Easy to bend and install, nylon tubes maintain shape under pressure—similar to metal pipes—without complex tools.

Chemical Resistance

Resistant to corrosion from many chemicals, nylon hoses last over 10 years in demanding conditions.

Electrical Insulation

Nylon’s high resistance makes it a reliable insulator for electrical applications.

Temperature Tolerance

It operates efficiently between -40°C and 100°C, adapting to diverse industrial environments.

Applications of PA Hoses

Given these strengths, nylon hoses serve various sectors:

Automotive: Fuel lines, air brake systems

Electrical: Cable insulation, wire protection

Machinery: Pneumatic tools, hydraulic systems

Textiles: Loom components, thread guides

As industries prioritize miniaturization and lightweight solutions, demand for high-strength nylon like PA6 and PA12 continues to grow.

Why Choose Everflex?

Everflex specializes in R&D, production, and export of premium nylon hoses. Our offerings include:

PA6 and PA12 tubes

Double-layer reinforced hoses

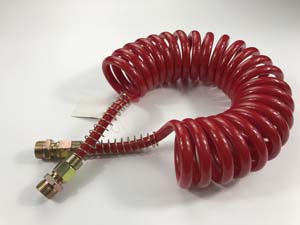

Coiled nylon solutions

All products meet rigorous quality standards, ensuring durability and performance. For tailored solutions or expert advice, contact us today.

Upgrade your systems with nylon tubes that combine versatility, strength, and longevity. Trust Everflex for reliable, industry-grade hose solutions.