Ultra high molecular weight polyethylene (UHMW-PE) is a thermoplastic that combines the best properties of most plastics. As a result, it resists impact, low temperatures, wear, and chemical corrosion. Additionally, it self-lubricates and absorbs impact energy—qualities that rank highest among current plastics.

In recent years, this new plastic has gained popularity in Europe and America, with demand steadily rising. Meanwhile, UHMWPE products are increasingly used in our country and are designated as a key promotion project for our industry’s future.

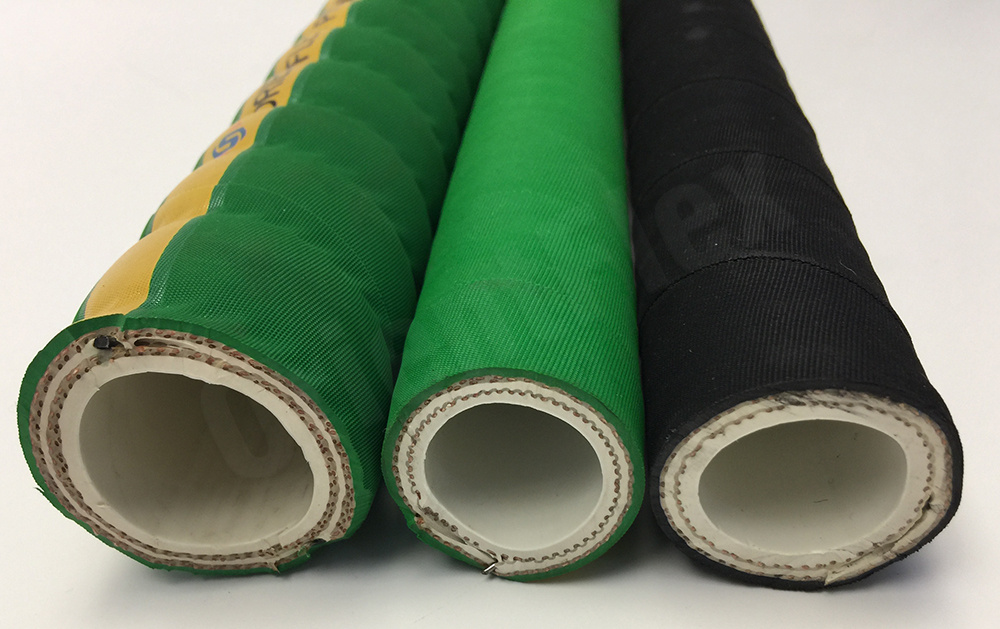

Typical applications include chemical and food-grade hoses. When made with UHMWPE, these industrial hoses exhibit significantly enhanced performance.

Production Process

UHMWPE uses a Ziegler-type high-efficiency catalyst low-pressure synthesis method, yielding molecular weights above 5 million. However, thermal degradation during processing means products with molecular weights over 1.7 million still deliver excellent performance.

Key Properties of UHMWPE

High Wear Resistance

Among plastics, UHMWPE offers the best wear resistance. Higher molecular weights enhance this property. And it outperforms many metals like carbon steel, stainless steel, and bronze. For example, UHMWPE hoses last 4–6 times longer than steel pipes under strong corrosion and high wear, boosting work efficiency by 20%. This makes it an ideal choice for energy-saving applications.

Corrosion Resistance

UHMWPE hoses resist corrosion in alkaline solutions and function normally in acids up to 80°C. They maintain stable performance in 75% sulfuric acid and 20% nitric acid, as well as seawater and liquid detergents.