In modern chemical industry, chemical hose plays an important roll. Because it can bear most of the chemicals. However, the normal chemical hose can’t fit the new industry. As the usage is more and more wide. So that the mediums become more. On such occasion, the composite chemical hose appears.

Composite chemical hose absorbs new material and new tech. Thus it has great properties as follow.

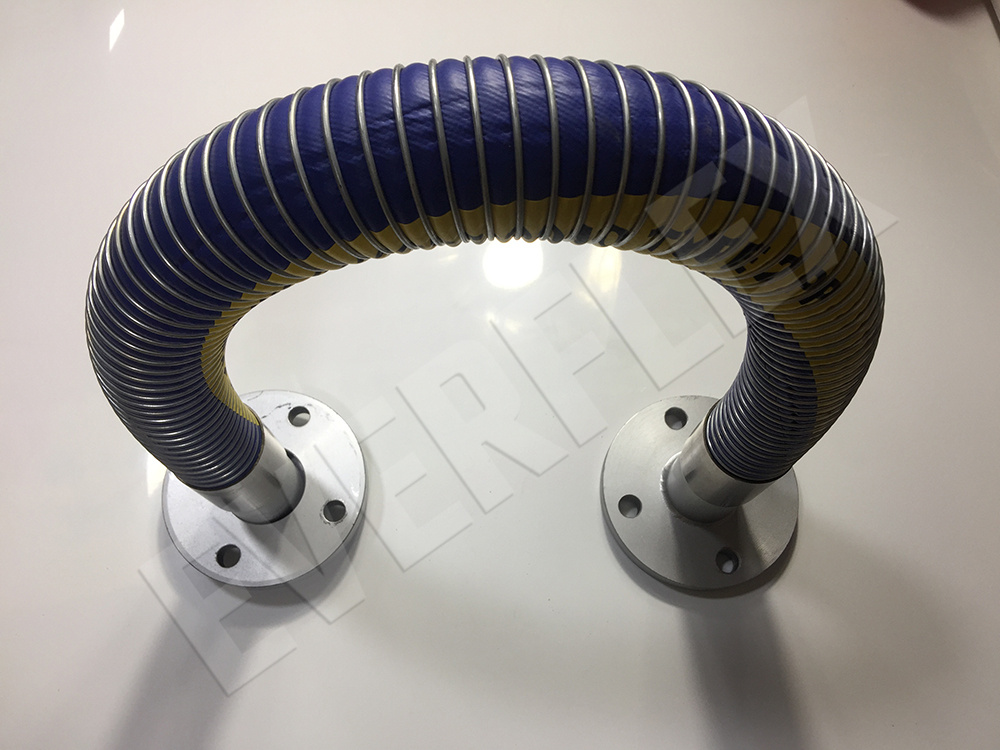

Flexible and small bend radius

Compared with rubber hose with the same specs, it’s 40% lighter. While the bend radius can be 1/3 of rubber hose. Besides, it’s very flexible. Thus it’s suitable for the uses with huge mobility. It’s also ideal for oil tank and oil tanker. Moreover, it can also work in narrow spaces, which is the unique property.

Pressure resistant

Composite hose can work at 1-4Mpa, while the negative pressure can be 0.1,pa. With the same situation, the pressure resistance is better than rubber hose. Because rubber hose is hard, and can’t bear pressure in heavy bending. When extremely bent, the inner wall folds and block the hose. But composite hose can work at extreme bending. At the bend point, the hose remains circle. Thus there will not be fold and block. Also there will not be crack.

Acid and alkali resistant

Because of synthetic resin, the chemical resistance is better than rubber and metal hose. Especially for acid and alkali liquid. Besides, it can work at -60℃-220℃.

Composite chemical hose is conductive

Because of pressure and crush, there will be static inside the hose. If not conduct it, there will be serious problem. Composite chemical hose can conduct the static. You just need ground the iron wire. It’s really safe and reliable.

EverFlex is your export in hose solutions. We make every effort to offer you the best hose. So if you have any questions about composite hose, fell free to contact us.