Clamp is a connector in pipeline system. It’s popular and it has wide usages. Next, let me show you the specs and features.

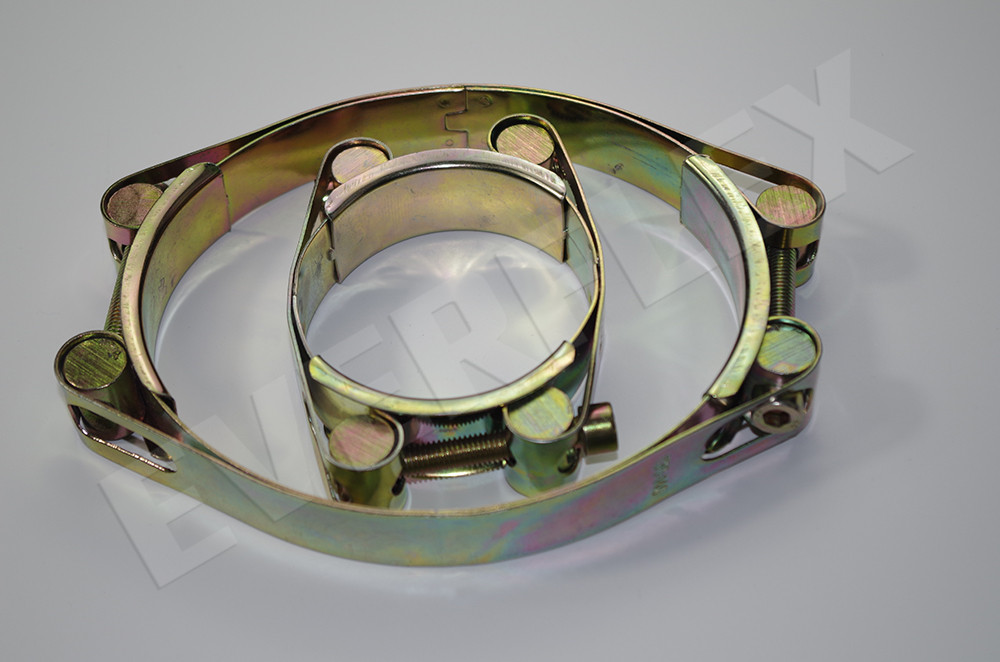

Specs of clamp

It has complete sizes. While the relevant standards are DIN, ISO, SMS and so on. Including, DIN standard has DN10-DN150 types. While ISO standard is 12.7-154.4mm. As for DN20-DN300, the diameter of stem is 2mm smaller than the stop-turning whole. While it can work at 5-68Mpa.

Different clamps has their own structures. As for the material, it can be zinc alloy, stainless steel and carbon steel. While the surface treatment could be zinc coat, chrome coat and scrub.

Application of clamp

The structure of clamp is very tight. Thus there was almost no air hole. Besides, it has excellent corrosion and acid resistance. Generally, it acts as the connector for hoses such as metal hose. Because of the special design and structure, it brings convenient and benefit to construction and repair. Therefore, it’s ideal for water deliver, metallurgy, power and building. Moreover, it’s also suitable for food, beverage and medicine use.

Features

Fast and easy

You can install the clamps directly without welding and coating zinc. Thus it makes your work fast. Besides, small quantity of bolts with special crimp design make it easy to install. In another hand, it’s easy to unload and clean.

Reliable

It can crimp by full circle. While the tensile strength on the end is very high. The C type gasket can be triple leakage proof. While the material of sealing can be customized based on the work condition.

Shock absorb

The space on the end can cut off the noise and shock. Then avoid the expansion and contraction. Besides, sealing gasket can absorb the noise and shock.

Safe and no pollution

When install the clamps, you don’t need any power, oxygen and open fire. Thus it makes the work safe enough. In another hand, the install don’t need welding. So it will not damage the coating.

Because of the above properties, clamp becomes one of the most used part. If you have any questions about it, feel free to contact EvertFlex.