Recent years, the station and people care more about the environment protection. Thus the new petrol station HDPE pipe becomes more and more popular. In fact, European and American Countries go earlier on such project. Now, over 80% of the petrol stations in western countries has replaced to HDPE pipe. While some developed countries in Asia and other places gradually changes to the HDPE pipe. While China is also working on such project. In the future, Africa and south America will also come.

Petrol Station HDPE Pipe Structure:

Inner tube: HDPE

Reinforcement: 1 layer of barrier and 1 anti-static layer

Cover: HDPE

Temperature: -40℃-50℃

Standard: EN14125

Application:

HDPE Petrol Pipe is specially designed for petrol station underground fuel line.

There is a special EVOH barrier inside the petrol station. While such barrier can effectively prevent the leakage of liquid and gas. Thus you don’t have to worry about the oil leaks. Even there was any leakage risk, you also don’t have to worry. Because the installation is with 2 pipes. The larger size hose covers the smaller one. Thus even the inner pipe has leakage risk, there is another pipe outside. In a word, the special twin body structure provides the safe guarantee to the fuel deliver.

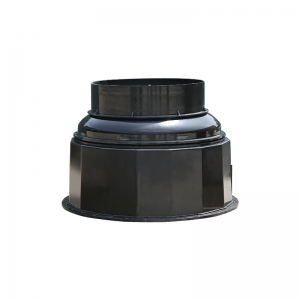

Underground HDPE pipe for petrol station adopts customized fittings. Including 45°elbow, 90°elbow, straight coupling, tee and reducing elbow. While the welding method is electric melting. Thus it avoid the open fire that in the traditional technology. While ensure the welding quality, it avoid the damage to the pipe. The joint also adopts the twin structure to match the pipe. In general, the project period can be 10-12 days for steel pipe. But it’s just 2-3 days for the gas station HDPE pipe.

Features:

Anti-static and safe for use

Long service life which could be over 20 years

Will never leak

Flexible, easy to transport and install

No need of anti-corrosion treatment

High pressure resistant

Eco-friendly