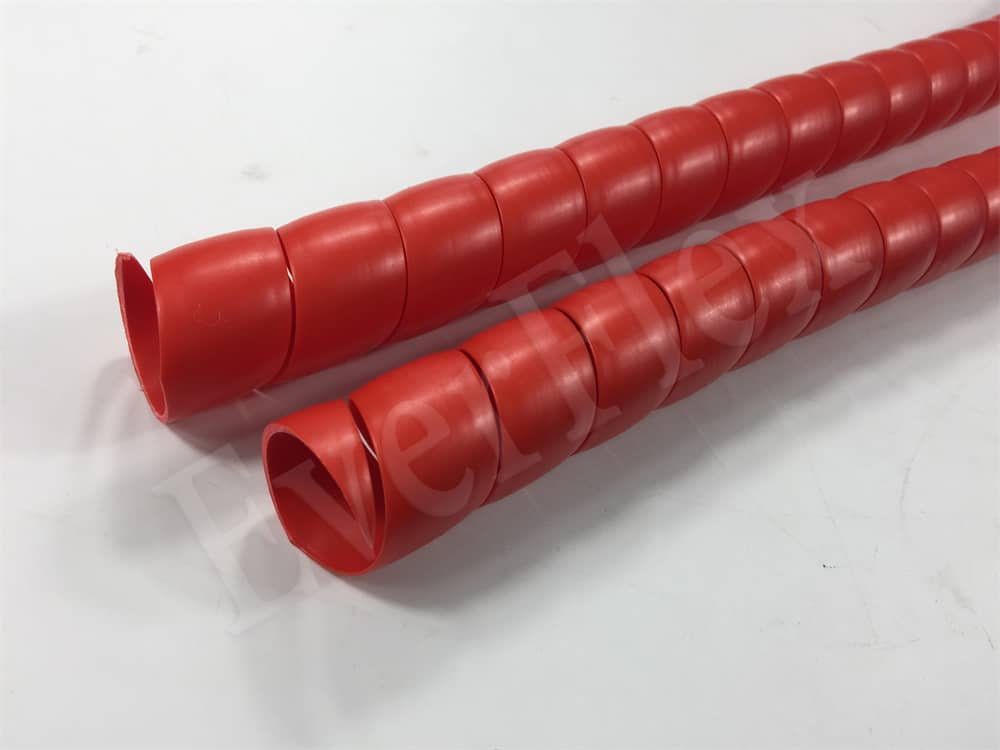

Spiral hose guard is a new type of protective cover used to replace traditional metal spring guards. It effectively protects hoses or cables from being scratched by friction. The spiral protective cover has excellent wear resistance. But what does this wear resistance have to do with?

Wear resistance is related to the environment of use

Wear resistance is only a relative concept. It is different from using it in a normal environment to using it in extreme conditions. Under normal conditions, both the protective cover and the product it protects have a good service life. But under extreme conditions, various factors will affect the protective cover to a certain extent, causing additional loss. For example, the spiral sheath used to protect the network cable at home is different from the protective cover used in mechanical equipment and underground mines. The harsh environment greatly accelerates the wear loss of the spiral protective cover.

Wear resistance is related to the production process

Even if the same material is used, but the process used is different, the products made will not be the same.Everflex uses advanced testing instruments and modern production equipment, and adopts mature hot winding qualitative extrusion process production line production. Therefore, the performance of the spiral protective cover is more stable and superior. Under normal use, the service life of the protected product can be extended to three years.