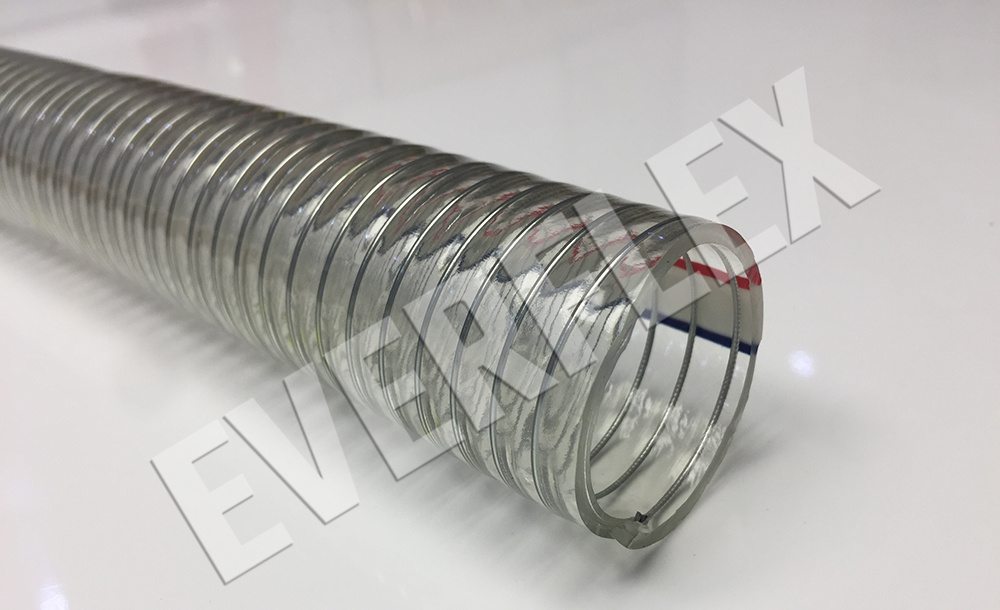

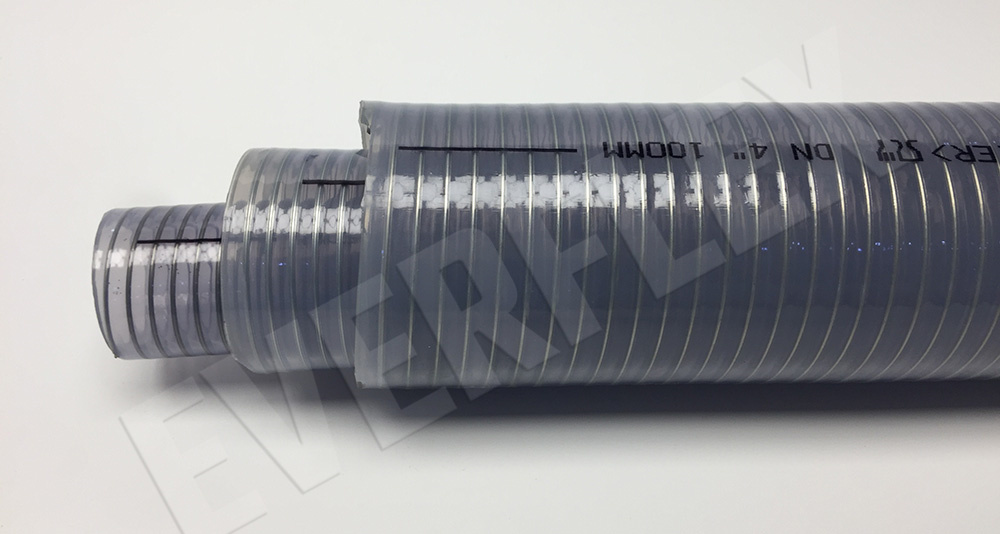

The new technology often serves in industry first. While PVC wire hose is such a new product with new tech. It has a smooth inner tube and a wear resistant cover. Besides, it has excellent corrosion resistance. Besides, PVC wire reinforced hose is not prone to age and brittle. Thus it has become the new favorite in the fields of machinery, petrol, chemical, etc. However, how to test the quality of such a PVC hose? Next, Everflex will show you 2 methods to test the hose.

Method for small size PVC wire hose

First, for the length of the sample, the min length should be five times the inner diameter. Or it can be 1 meter long. Of course, this does not include the end hose connector. We can choose the larger one.

For the steel wire hose which is less than 1 meter, you can take the entire hose. As for those hoses with an inner diameter of 80 mm or less, lay it on a flat surface first. It is best to use a metal plug to block one end to prevent air leakage. Then insert a solid ball into the hose. Connect to the vacuum pump at the opening, and attach a vacuum gauge. After that, reduce the internal pressure value to the test pressure value within 60 seconds. Then keep this value for at least 10 minutes. At the same time, you can check the external dent. Finally, tilt the hose so that the solid ball passes inside the entire hose.

While for some large steel wire reinforced PVC flexible hose, you can use another method. The basic situation is the same as above. But you need to use light instead of a ball to check the inside. Then see if there are any dents, dryness, etc. on the outside.