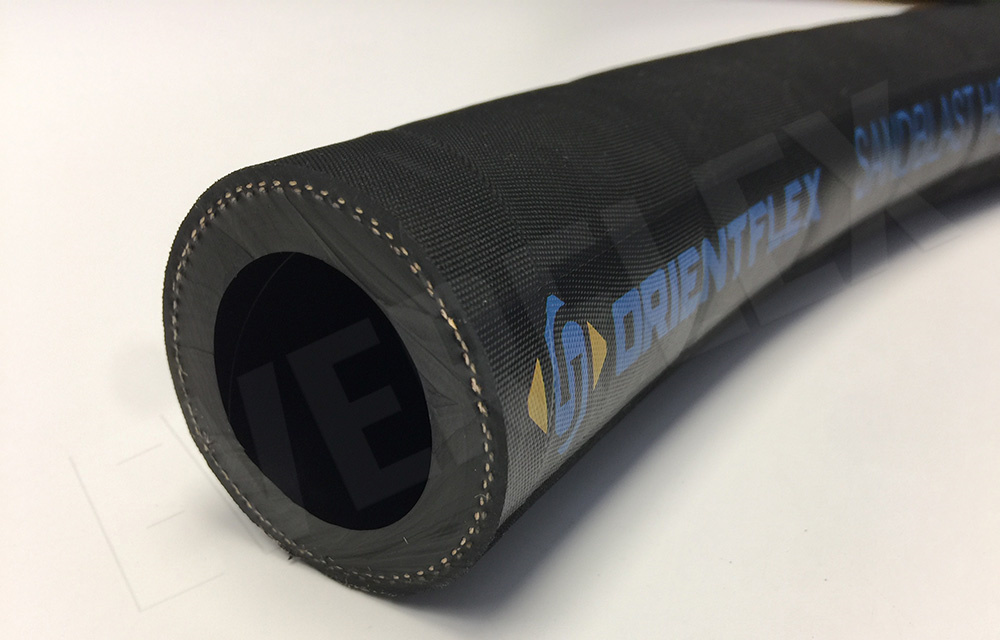

Sandblasting hoses are generally divided into light sandblasting hoses and heavy sandblasting hoses. While it’s according to the working conditions and the degree of loss of material particles to the conveying medium. The spiral steel wire will make it suitable for negative pressure environment

Light-duty sandblasting pipes are usually used in environments such as sandblasting on ships and quicksand operations. The common inner rubber is made of wear-resistant NBR material. And the outer rubber is packed with composite rubber.

Heavy-duty sandblasting pipes are used for equipment sandblasting gravel, fine pebbles, mud and other environments.

Sandblasting hoses are mainly used for the transportation of fluids containing solid particles such as particles, gravel, cement, quicksand, concrete, gypsum, etc., and are suitable for various engineering operations such as tunnel projects, wells, and caverns. The inner rubber and outer rubber of sandblasting pipes are usually made of wear-resistant materials, mostly NBR , SBR , etc., or there is a kind of PARA rubber with better performance for imported hoses (Trefoil rubber). It is widely used, mainly in the sandblasting industry, as well as cement, metallurgy, minerals, port terminals, municipal construction, transportation and other industries. Its main feature is wear resistance, and it can be seen when wear-resistant pipes are needed.