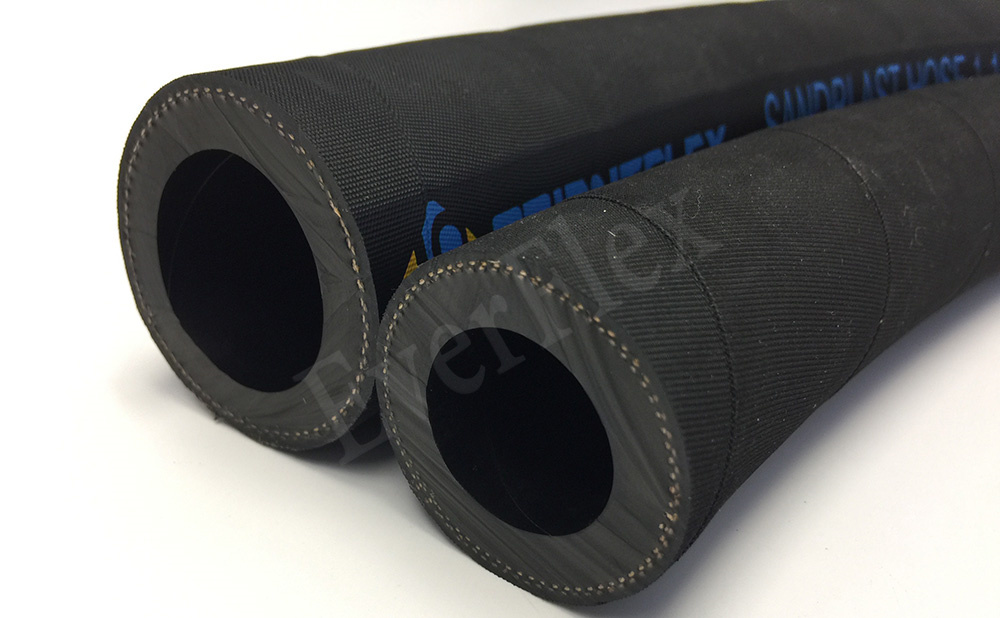

High pressure rubber hose is a series of industrial hose that for high pressure work. For example, sandblast hose is to spray shot at high pressure. While high pressure washer hose is for the clean work. It can bear 20Mpa. Then hydraulic hose like SAE 100 R1 and SAE 100 R2 is to deliver oil.

During the use, you may find that the high pressure hose fails earlier than the designed service life. Then what cause that? Let’s analyze the reasons next.

Heat and severe pressure cause high pressure rubber hose crack

The rupture of high pressure hoses is caused by pressure. During the operation, the pressure will suddenly appear or fall in the hydraulic oil hose. While it will rebound and impact the oil hose. Then it cause damage to the oil seal. Besides, it cause leakage on the hydraulic hose fittings. Thus when you operate the hose, you should be gentle.

The joint of high pressure rubber hose is incorrect

When replace the high pressure hose, confirm the length and fittings first. Then try to reduce the bend of the flexible rubber hose and tighten the union. In addition, do not bend the hose nozzle. While for the part that is easy to wear, take some measures to prevent burst.

Oil temperature is too high

In the operation of the project, the hydraulic system will increase due to the oil heating. As well as the influence of rapid temp, especially in summer. Then the rubber will easily age with the worse elasticity. Besides, the worse the strength and sealing. Then the pressure rubber hose will burst. Therefore, when the temp rise of the hydraulic system is too high or too fast, check the reason and deal with it.

Everflex is a hose manufacturer which focus on the hoses and fittings. After 17 years’ effort, we are now a global supplier for hoses and connectors. While Everflex hose is more and more popular. If you need a hose like PVC suction hose, PVC layflat hose, rubber discharge hose and others, welcome to inquiry us.