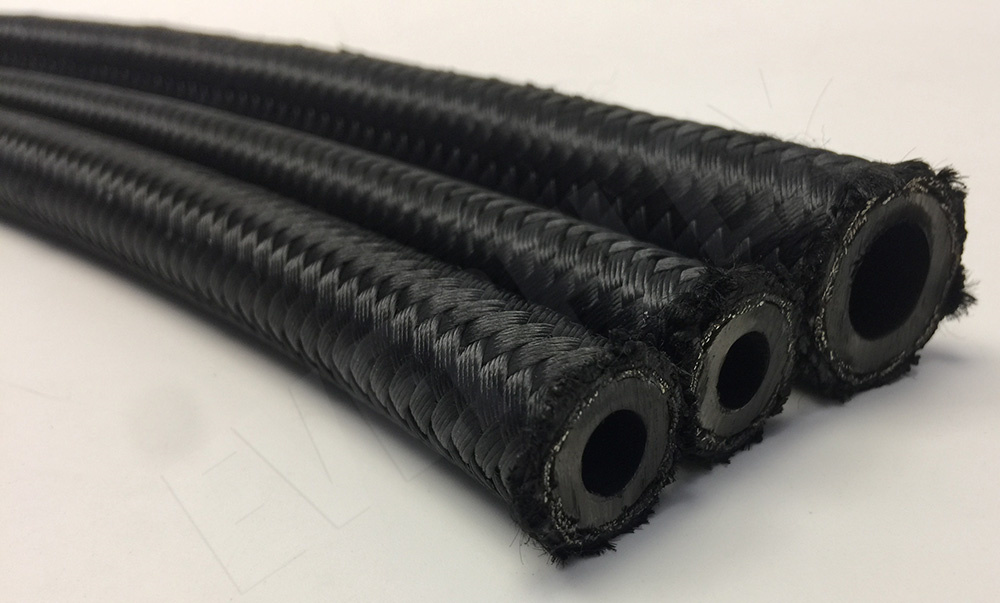

Hydraulic pipe is a flexible hose to deliver hydraulic oil. And it is the necessary part for hydraulic systems. In general, such high pressure hose has a long service life. However, you should maintain it regularly. Because only this can guarantee a full service life. But in fact, many people don’t know how to maintain hydraulic hose. Then next, let me show you the methods.

Shift maintenance of hydraulic pipe

This is a routine maintenance before, after and during work. Although the content is not much, it is important to ensure normal operation and reduce failures.

1. Before and after operation, clean the exposed parts and keep the machine clean

2. Check if the parts of the machine are damaged and if the fasteners loose, damage or lost

3. Check the fuel, oil and cooling water to see if they are enough.

4. Check if there is water or oil leakage from plastic hoses

5. Check if the electrical system connector is loose. And find out if the battery is running low. Besides, confirm if the lights are intact and if the control device is flexible and reliable.

6. Listen for abnormal noises from the engine and working parts. Then test if the braking is reliable and if the steering is flexible.

Once you find any leakage on the hydraulic hose, change new ones at once. Because this will cause leakage of oil and pressure. Besides, if the joints loose, tighten them well to prevent fail. In a word, check all the factors and keep each of the hydrualic pipe works well.