As a great material, EPDM rubber appears in everywhere of our daily life and industries. Today, let’s have a brief understanding of it.

What is EPDM rubber

EPDM rubber is obtained by copolymerizing ethylene and propylene in solution. It’s a saturated polymer.

What are the characteristics

EPDM rubber has excellent weather, aging, chemical corrosion resistance and electrical insulation. It’s flexible and impact resistant, while the most important features are as follow:

Good filling property

EPDM rubber has low density which is 0.87, and that means you can add filler to reduce the cost to make up the disadvantage of high price of EPDM rubber. The filler will not affect the mechanical property seriously.

Aging resistance

EPDM rubber has excellent weather, ozone, heat, acid and alkali resistance. It can work in 120℃ for long term and shortly in 150-200℃. Add certain antioxidant can increase the working temperature. With ozone concentration of 50pphm and stretching of 30%, you can use EPDM rubber more than 150 hours without cracking.

Corrosion resistance

EPDM rubber lacks polarity and has low degree of unsaturation. So it resists to polar chemicals like alcohols, acids, alkali, oxidizing agents, refrigerants, ketones and fats.

Steam resistance

EPDM rubber has excellent steam and heat resistance. It tested that the appearance doesn’t change after 100 hours in 230℃ overheat steam. While the appearance of other rubbers nitrile rubber will turn to bad with the same condition.

What are the applications

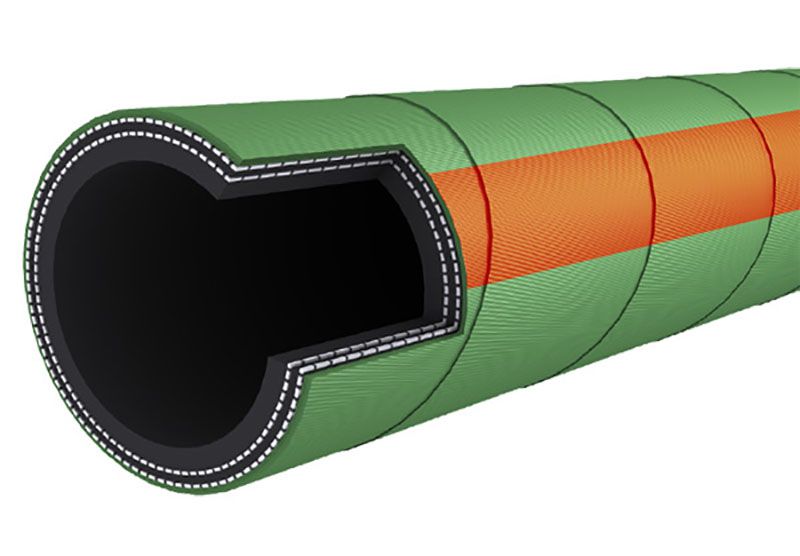

For the excellent properties, it’s widely used in for wire, gasket, seal, waterproof material, protecting sleeve, hoses and rubber sheet in car, constriction, military industry, aerospace and many other applications.

We learned EPDM rubber this time. If you have any questions about this material and its products like hose, welcome to contact us. OrientFlex will offer you the best products with competitive price.