In modern industry, you need many kinds of hoses. With different materials, they can be plastic hose, rubber hose, silicone hose, stainless steel hose, etc. While for the pressure resistance property, they can be high pressure hose and low pressure hose. Typical high pressure pipes are hydraulic hose and washer hose. While low pressure hose are commonly water hose and oil hose. Then next, let me introduce you low pressure rubber hose.

What is a low pressure rubber hose

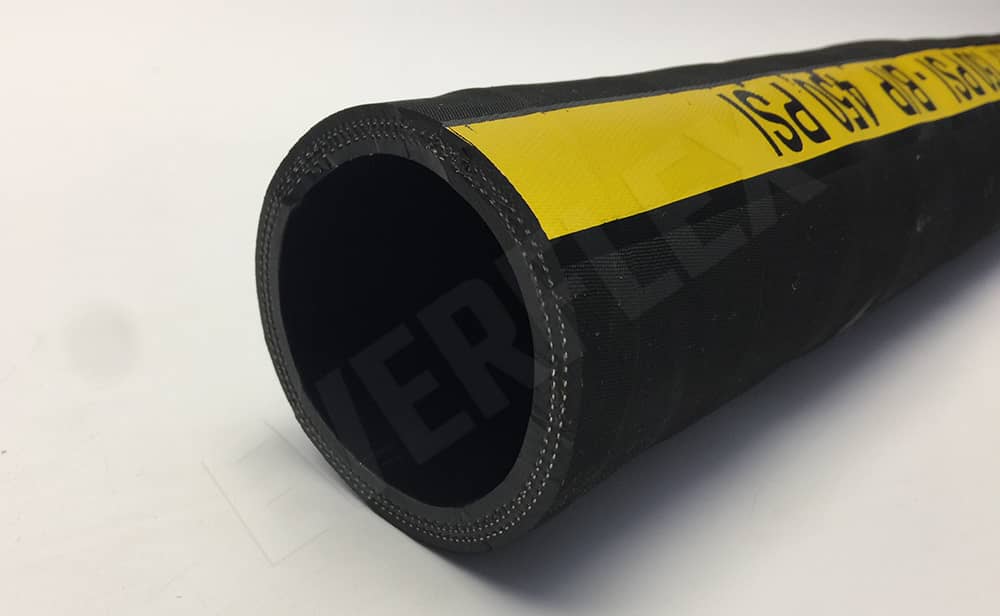

The low pressure pipe adopts a cold feeding process. First, feed the raw material in an internal mixer. Then it will through a filter to filter out the impurity. Then they will enter into sheets with a press and then cut into pieces. Then put it into the extruder to extrude the inner rubber layer. But the extruded inner rubber is uniform with a high density. The middle rubber layer is fire braiding. Thus it is more even and tight to bear greater pressure. Then the outer rubber enters the extruder and then wrap it with a water cloth. The water cloth is evenly. So that the surface can be smooth and neat.

Low pressure rubber hose application

Such rubber pipes widely serve in chemical, machinery, electronic, military, pipeline, etc. The low pressure hose consists high grade PTFE hose, braided mesh and stainless steel cover. Thus it performs very well in high temp, corrosive and high pressure conditions.

Low pressure hoses can withstand 250℃ high temp steam under an air pressure of 3kg/cm2. While the skin temp does not exceed 60℃. Thus it can ensure a safe operation.