Oil transfer hoses are mainly used in the application of fuel, diesel, paraffin and oil.

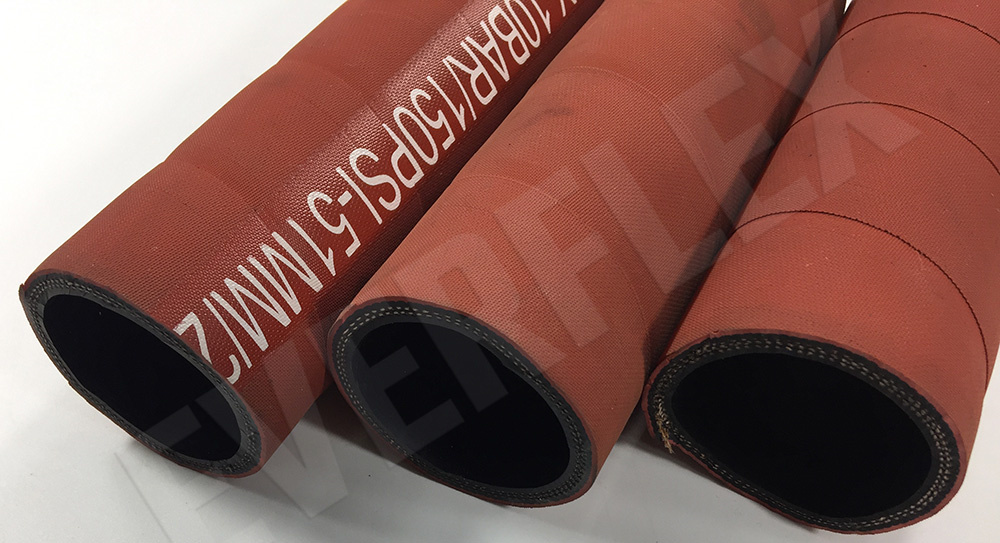

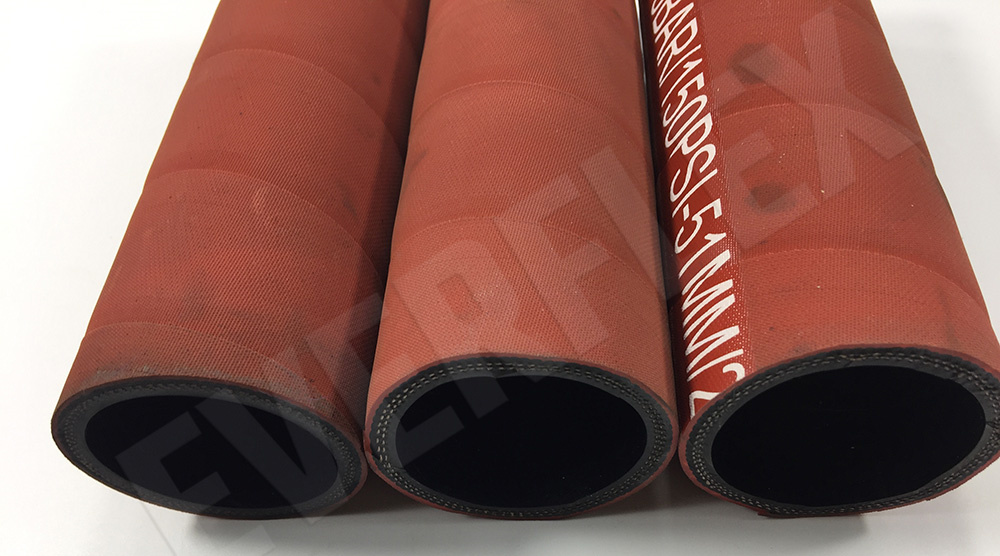

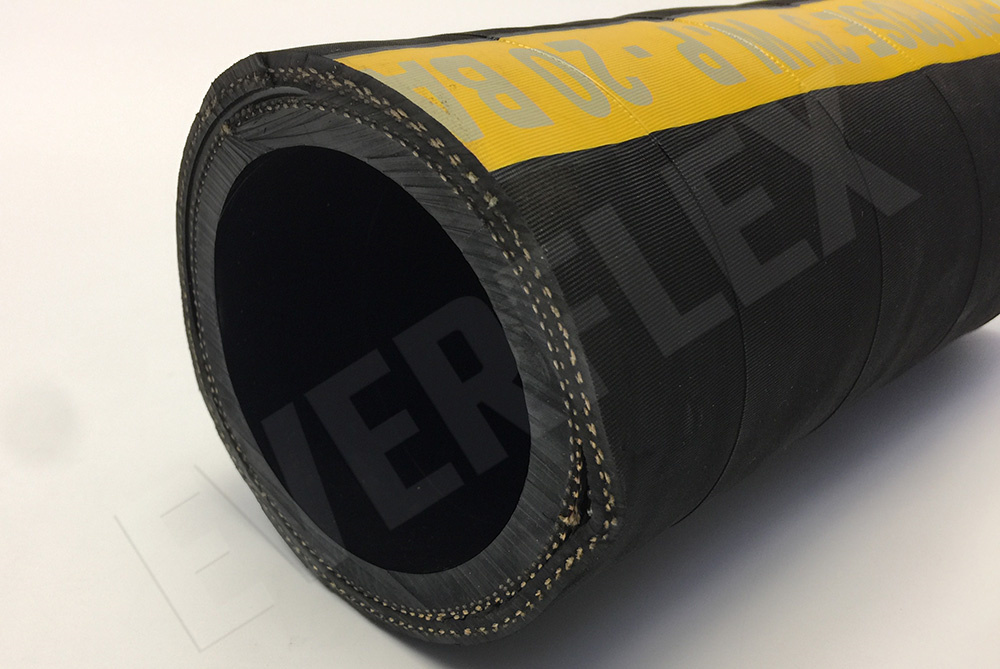

The inner rubber material of the oil delivery hose is made of NBR, PVC composite, R and other materials. Usually there are conductive steel wires between the inner and outer rubber to prevent sparks.

Then, the oil delivery hose in the inspection need to pay attention to the main matters are.

1, oil delivery hose in the process of use need to be regular maintenance and inspection of the hose. If abnormalities are found, they should be replaced in time.

2, before using the oil hose, the appearance of the hose should be carefully checked. Confirm that there is no trauma, hardening, softening, discolouration, etc. on the appearance of the hose.

With the development of industry, the various products needed to be used in engineering are more stringent than those used in other places. Especially in comparison to civil hose. With the complexity and harshness of the industrial operating environment, the equipment for the hose quality star requirements are also more demanding. Therefore, the need to be made in the production of more norms and standards, the use of industrial hose is very wide range.

The oil transfer hose is light in weight, tough, easy to handle, soft, flexible in use, low temperature, no deformation and resistant to seawater corrosion.

Oil transfer hose is a pipeline for transporting petroleum crude oil or petroleum products. Due to the excellent characteristics of the oil transfer hose itself, such as good pressure resistance, strong flammability and sex, it is widely used in various industries.

Oil transfer hoses are mainly used in petrochemical plants, terminals, filling trucks, barges, tankers etc. The inner diameter size is changed depending on the amount of oil to be transferred. Transport of various aromatic compounds such as diesel, petrol, aviation paraffin, heavy oil, etc. The use of oil hoses for transport services saves transport equipment and costs and saves energy.

The oil transfer hose is light, flexible and can be freely bent, with good resistance to positive and negative pressure, strong heat resistance and oil resistance, so it can be widely used to transport crude oil, fuel oil, food oil or chemical solvents.

The following is a description of the advantages of the oil hose:

1, lighter texture: generally speaking, the oil hose will be 30% lighter than the hose with the same specifications, thus reducing the labor intensity of the operator, easy to operate, can well accelerate the work efficiency;

2, good flexibility, can be freely bent; even in a small turning radius can also work normally;

3, has good resistance to positive and negative pressure performance, high working pressure up to 4.00MPa, negative pressure up to 0.10MPa; 4, excellent heat-resistant performance;

5、Excellent oil resistance;

6, with the electrostatic export function, so can transport flammable goods.

Notes on the use and maintenance of oil delivery hoses. Hoses that meet one of these criteria should be scrapped:

1. Denting or twisting of the exterior.

2. Movement of the inner and outer steel wires.

3. Corrosion or wear of the outer steel wire.

4. Loose or leaking joints.

5. A multimeter or ohmmeter should be used to check that the ends of the hose are not connected.

6. Joint is corroded. Worn or damaged by other external forces.

Oil delivery hose routine maintenance cleaning methods.

Oil delivery hoses should be cleaned after use, before testing or before long storage.

The cleaning method should be determined by the environment and use of the hose. In the cleaning process, one end of the hose should be grounded.

1. It can be cleaned with tap water, hot water, detergent, normal dissolving solution at room temperature or sea water. If seawater is used for cleaning, drain the seawater inside the tube after cleaning to prevent the hose from being corroded by seawater.

2. for the transport of strong acidic media hose, in the cleaning before the residual media to drain clean, to prevent cleaning should be friction heat generation reaction.

3. The hose used for conveying gelatinous media, there should be no residue in the tube after use to prevent the hose from reacting when it is used next time. You can also use hydrogen gas. Steam or air cleaning hose, but the temperature should not be too high, and the ends of the hose open, so as not to damage the hose.

If you have any further questions about oil transfer hoses, please feel free to ask Everflex.