When using concrete pump pipes, the following points should be noted to ensure construction safety and efficiency:

Shorten the length of the pipeline and reduce the use of elbows and hoses. This helps to improve pumping efficiency and reduce the probability of failure.

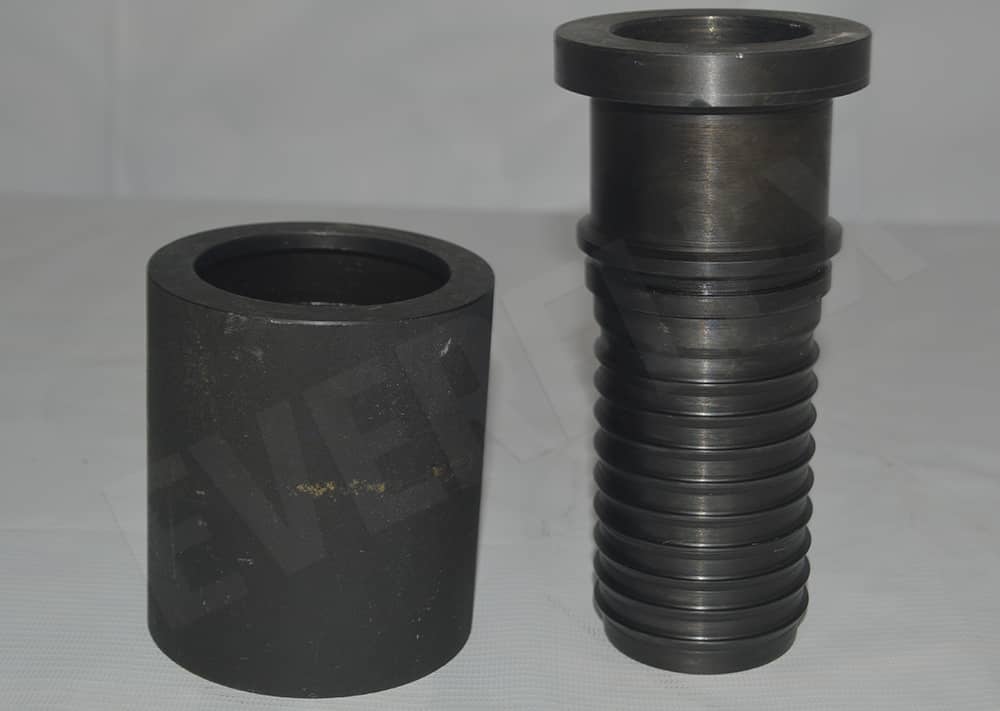

Use of new and old pipes

New concrete hose should be arranged in places with high pumping pressure to give full play to their performance advantages.

Precautions for vertical upward piping

A certain length of horizontal pipe should be laid between the concrete pump and the vertical piping. Sufficient resistance is formed to effectively prevent the backflow of concrete.

Fix the pump pipe

The pump pipe should be firmly fixed, especially at the bend. Then this can prevent movement or vibration from affecting the pumping effect.

Check the pump pipe status

Frequently check whether the pump pipe has cracks, bumps and bends. In addition, test whether the joints are tight and whether the strength meets the requirements.

Summer protection measures

In summer, open-air horizontal pipes should be wrapped with sacks and moistened with water. Because the concrete collapses too quickly under high temperature. Then it will cause pipe blockage.

With these suggestions, you can avoid many problems during the use of concrete hose. Besides, it can improve the construction efficiency and guarantee the safety. If you have any other questions, just consult Everflex. And we will offer you the best solution.

#concrete pump pipes# #concrete hose#