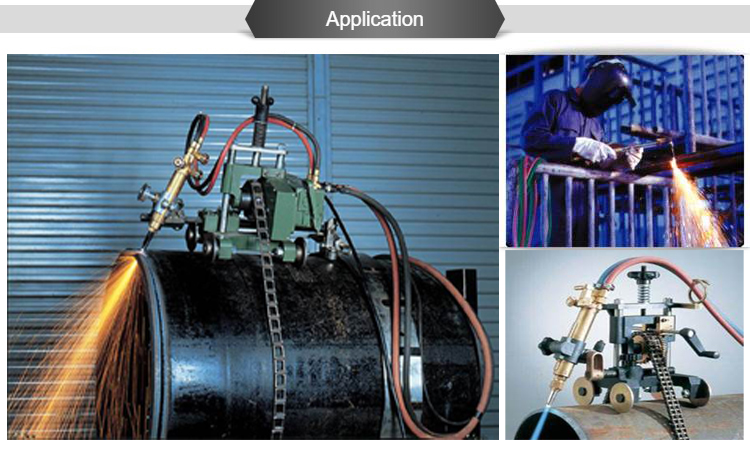

The oxygen welding hose is designed for high-pressure applications. It is a superior replacement to conventional rubber hoses as it is made of PVC. This results in convenience due to lightweight and economy in use. Oxygen and acetylene hoses has superior consolidation and adhesion between the braids and covers, as compared to rubber hoses. This hose is highly acknowledged for it qualities. Such welding hose is suitable for oxygen transport for all oxygen-acetylene welding, brazing, soldering and cutting operations. Due to light weight and flexibility, hose oxygen acetylene is also preferred for long distance welding applications. This hose is available in different specifications such as length, color, working temperature & pressure and size.

Before using the hose, check it entirely to see if it’s in a good condition. Besides, check if there was any crack or leakage problem. Because the hose concerns to your safety directively.

Structure:

Tube: PVC material

Reinforcement: high tensile polyester or cotton braid

Cover: PVC, green, blue.

Applications:

Being widely used in welding machine, architeture and lacquer factory

Features:

●High tensile polyester reinforced

●Work under high pressure 300psi

●Strong peeling adhesion between fire and PVC

●light, flexible, non-kinking, non-twisting, UV and ozone resistant, weather resistant

●Can be used for jackhammer hoe

Temperature: -10℃(-50℉) to 65℃(+150℉)