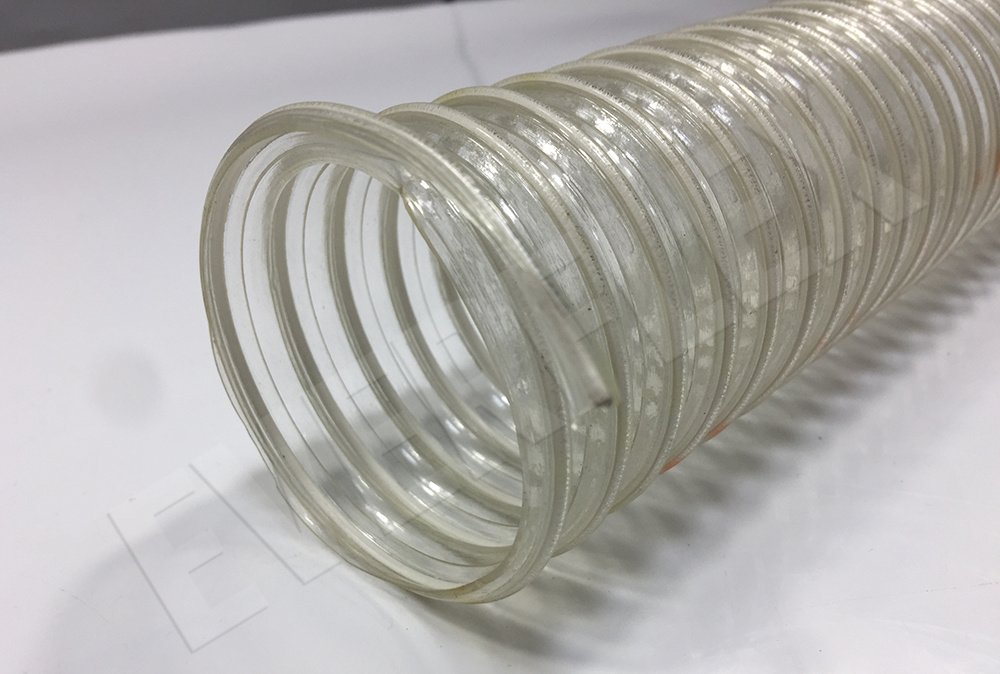

Plastic hose is one of the most common material in production and our daily life. While among them, the most used are PVC hose and PU hose. Then what are the differences between them?

Chemical composition

PVC is a synthetic resin made by polymerizing vinyl chloride monomer. PU is made of polyurethane. The molecular structures and chemical properties of these two materials is different, so their physical properties and processing characteristics is also different.

Temperature range

PVC hose is resistant to temperatures between -5℃ and 65℃. PU hose have a wider temperature range. The lowest temperature can reach -40℃, and it can reach 125℃ for a short time.

Weather resistance

Because PVC contains chlorine in its molecular structure, it has a certain UV resistance. But not as good as PU. PU materials will not fade or deteriorate after long-term exposure to sunlight. PVC hose may have problems such as yellowing and brittleness.

Wear resistance

PU hose is more wear-resistant than PVC hose. Because PU hose have higher wear resistance. This makes PU hose have a longer service life when pumping large particles and high wear materials.

Softness

PU hose is softer than PVC hose under the same wall thickness and wire spacing. However, it should be noted that if too much plasticizer is added to the PVC hose, its softness will be far from meeting environmental requirements.

Performance

PU hose has high wear resistance. The wear resistance is 2.5 to 5 times that of most rubber materials. It is 4 to 5 times that of most soft PVC materials. It has a smooth interior and good resistance to mineral oils and chemicals.