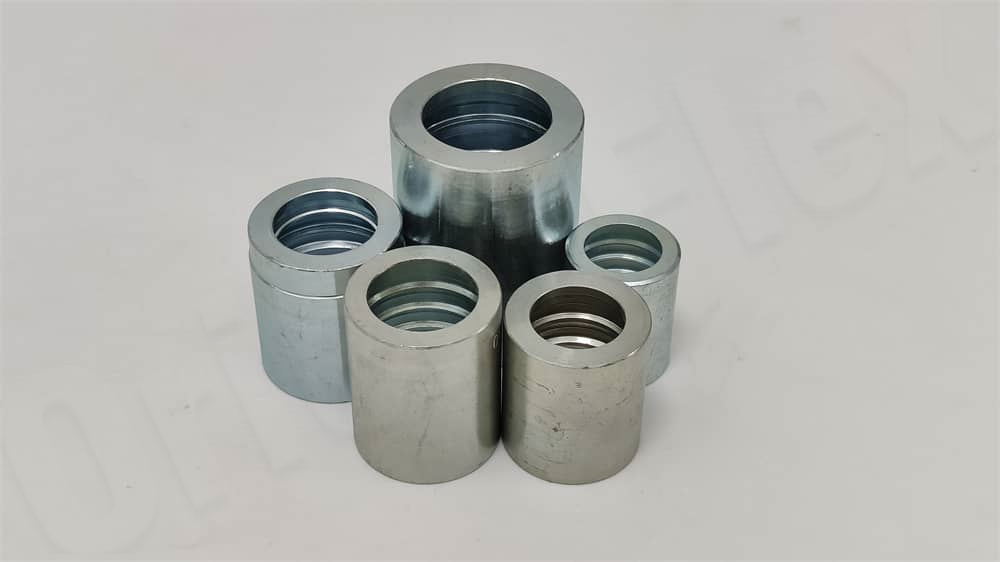

Ferrule type hose fitting is suitable for pipeline systems with oil, steam and water as media. They have a series of advantages such as advanced structure, good performance, easy use, no welding, etc. In addition, when using this type of fitting, it is not necessary to expand the pipe. Therefore, ferrule type hose fittings have been widely used in hydraulic and pneumatic systems of various types of machinery. Ferrule manufacturing precision is high and the process is complex. So it is not suitable for small batch production and requires professional production.

Features of ferrule type hose fitting

The biggest feature of the ferrule type is that it is very easy to install. It can be installed with a wrench. The ferrule type hose fitting tightens the ferrule within the 24° cone of the fitting by tightening the nut. While the ferrule bites the steel pipe, an effective hard contact seal is formed. The use of elastic ferrule sealing ring technology can further improve the anti-leakage ability of the ferrule type hose fitting. In addition, compared with the welded type hose fitting, the cleanliness of the pipeline will not be polluted by the production of oxide scale during the installation process. Therefore, the ferrule type hose fitting is widely used in high and low pressure ordinary pipeline systems.