Selection criteria for acetylene delivery hose

Material

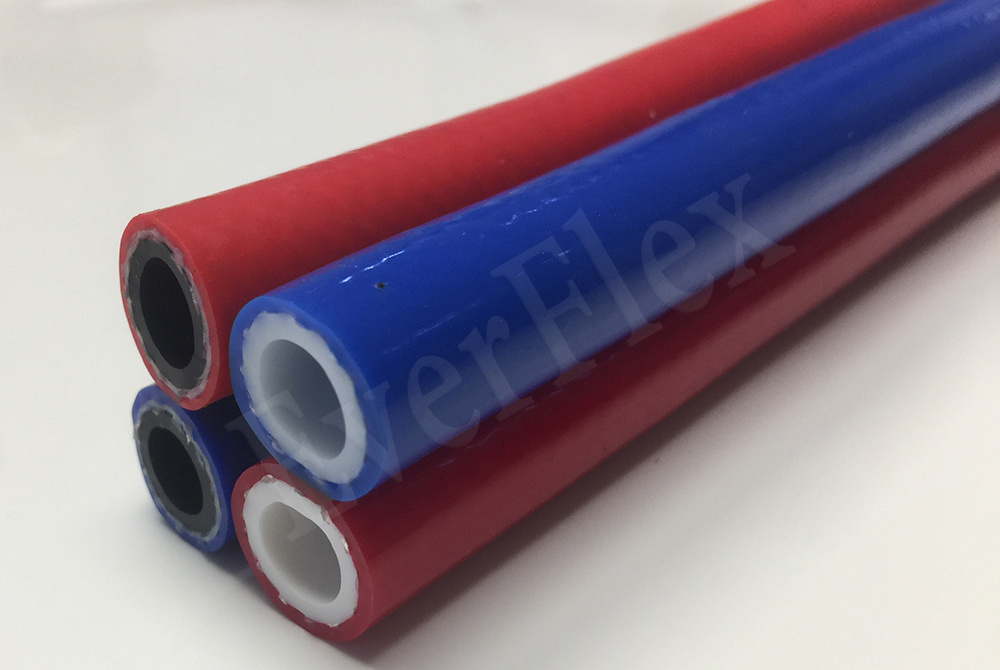

High quality acetylene delivery hose should use special synthetic rubber which is wear, corrosion and high temp resistant. You can also use PTFE hose because it has good compressive resistance and tensile strength.

Inner diameter

The inner diameter of the acetylene hose should match the outlet of the cylinder. Because only this can ensure a smooth gas flow. In addition, a large diameter hose can increase gas flow rate. Then it improves the welding efficiency.

Acetylene hose length

You should choose welding hose length according to the actual use scenario. In general, the longer the length, the greater the pressure loss. Therefore, on the premise of ensuring convenient operation, try to choose a shorter acetylene hose.

Number of elbows

The number of elbows in the hose should be less. This can reduce gas flow resistance and reduce acetylene gas loss.

Sealing performance

High quality acetylene delivery hose should have good sealing performance to prevent acetylene gas leakage. So you can check if the sealing ring of the delivery hose is intact and if the interface is tight.

Safety performance

Acetylene delivery hose should have certain safety performance, such as explosion-proof and anti-static. Therefore, pay attention to relevant product certification and safety indicators.

Precautions for purchasing acetylene hose

Understand your own needs

Before the purchase, you must first understand your actual needs. Such as gas flow, welding equipment type, etc. In this way, you can buy the most suitable product for yourself.

Consult professor

If you have any questions, you can consult industry insiders or expert to get more accurate advice. Everflex has worked on manufacturing and exporting flexible hoses since 2009. With 15 years’ experience, we can provide you the high quality hose with unique service. While you can not only get the best solution, but also save much time and budget cost. Contact us now and get the best purchase experience.