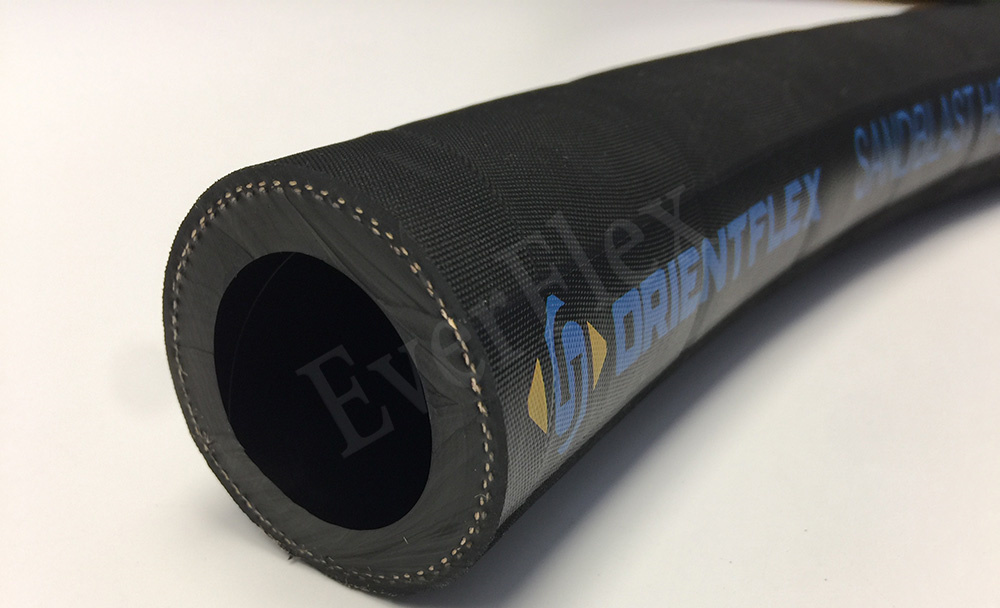

A blast hose is a rubber hose to convey abrasives such as shot and sand. It adopts natural rubber tube covered with an SBR cover. While this provides excellent wear resistance. Certain types of anti static tubing prevent sparks from igniting dry material inside the hose and nozzle. Blast hoses are widely used on construction sites, shipyard and mining.

Shot Blast Hose Structure

Blast hose is to move abrasive media or others in a blast machine. It has a thick inner rubber tube that resist wear. In addition, it has a synthetic fiber reinforce. While it is to bear the constant wear and tear. What’s more, it makes the hose can bear higher pressure.

Blasting Hose Usage

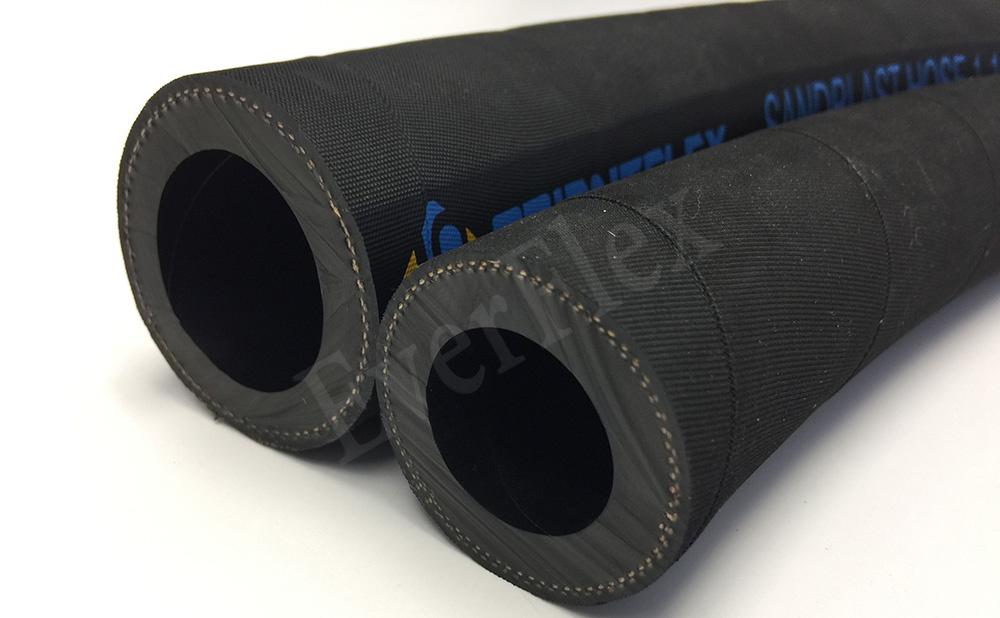

Rubber Blast Hose is a material handling hose for a variety of use. Usually, it is flexible. Thus it allows it to move freely.

Sand blasting hose and nozzle can transfer abrasives such as glass bead, grit, sand, etc. This type of hose can be in lengths of 50 feet. Besides, it can also work at -40 to 150℉. In addition to the standard length, you can ask for any other lengths.

The rubber blasting hose is made of high wear proof rubber. Thus it is very durable. As a result, it has a long service life and can last for years. While the abrasive content of a hose plays an important role in its life span. A high quality blaster hose will last three to five times longer than a normal type hose. You should test the pressure of the hose with a special pressure gauge to ensure its long term ability. While you should replace it if the pressure is below 1 atmosphere.

When you need to buy a sand blast hose, the anti wear ability is the first to consider. Because that determines the speed and quality of the blasting work.