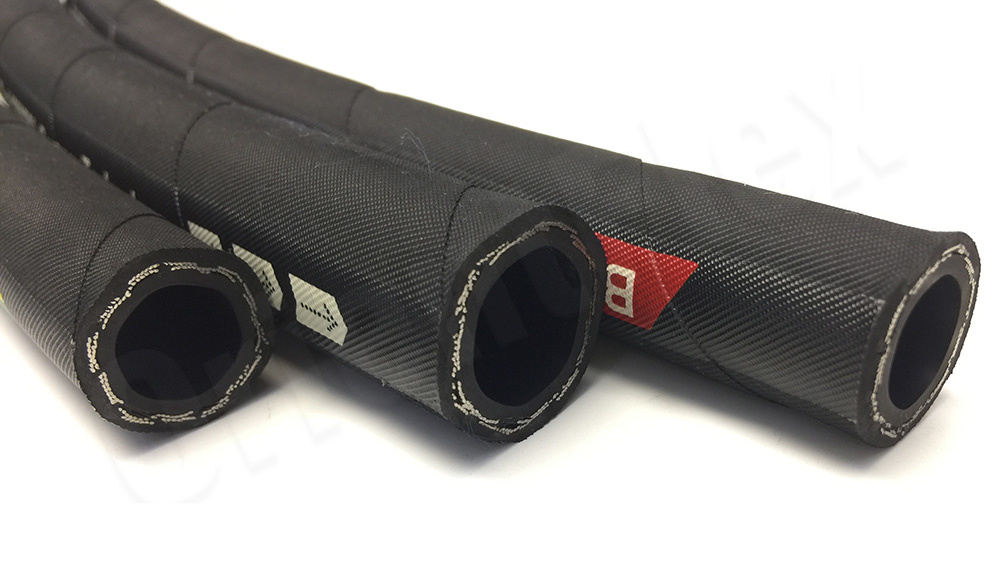

When the ultra-high pressure cleaning machine is in working condition, the hose must not be twisted and bending should be avoided as much as possible. If bending is necessary, ensure that the bending radius is not too small, generally not less than 15 times the outer diameter of the pipe, otherwise the outer steel wires of the reinforcement layer will be stretched and the inner steel wires will be compressed, thereby reducing the strength of the entire ultra-high pressure hose. Pressure strength ultimately affects the service life of the hose.

When the ultra high pressure cleaning machine is in working condition, the ultra-high-pressure hose cannot be crushed by heavy objects, hit by sharp objects, or bent. The outer layer must be protected from excessive wear. The high pressure pipe used for suspension must be firmly fixed at a short distance.

During the specific cleaning operation, try to avoid frequently opening and closing the hand-held high-pressure spray gun in order to reduce the impact of pressure pulses on the hose and extend the service life of the hose.

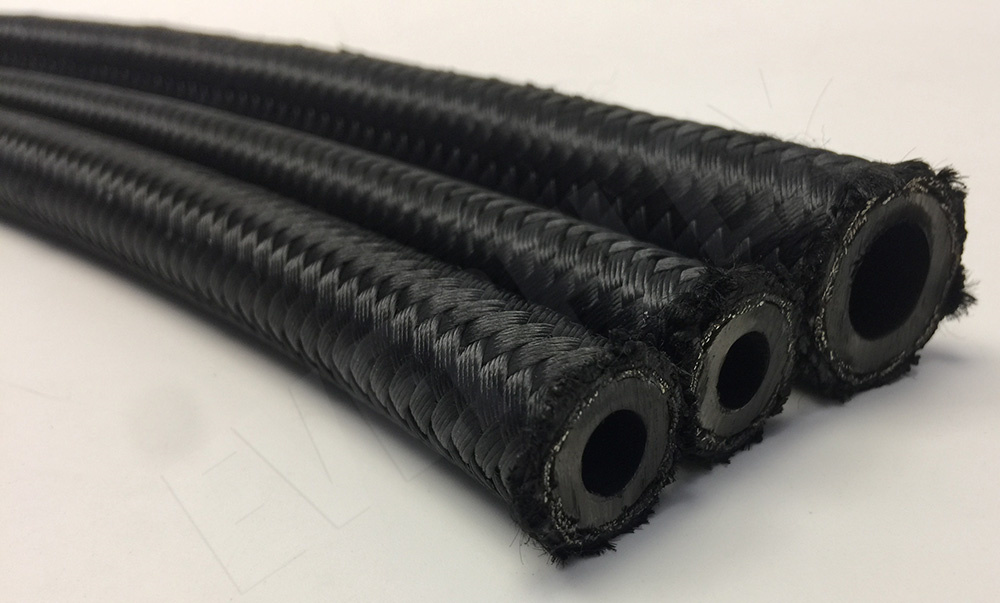

When the joints fall off or are damaged, it may cause injuries to people. You can steel wire braided protective sleeves at the connection points to connect both ends.

When you install and disassemble ultra high pressure hose, do not forcefully dismantle or twist them. Protect the threads of the connecting threads. At the same time, it is required to apply lubricating oil on the outer surface of the threads.

When the ultra-high-pressure hose is not used for a long time, the internal water should be drained. And the hose should be bent into a roll according to the specified size and laid flat. Special attention needs to be paid to the bends near the joints of ultra-high pressure hoses. The joints should be coated with anti-rust oil to avoid contact with high temperature, high pressure and highly corrosive media.