Deionized water is water that has been treated through multiple processes. It is colorless and odorless. Thus it has no harmful substances and no infectious bacteria. It is therefore considered high quality water. In the industrial and laboratory fields, the transportation of deionized water is a very important link. Choosing the right delivery hose is key to ensuring the quality of deionized water.

So how to choose deionized water delivery hose?

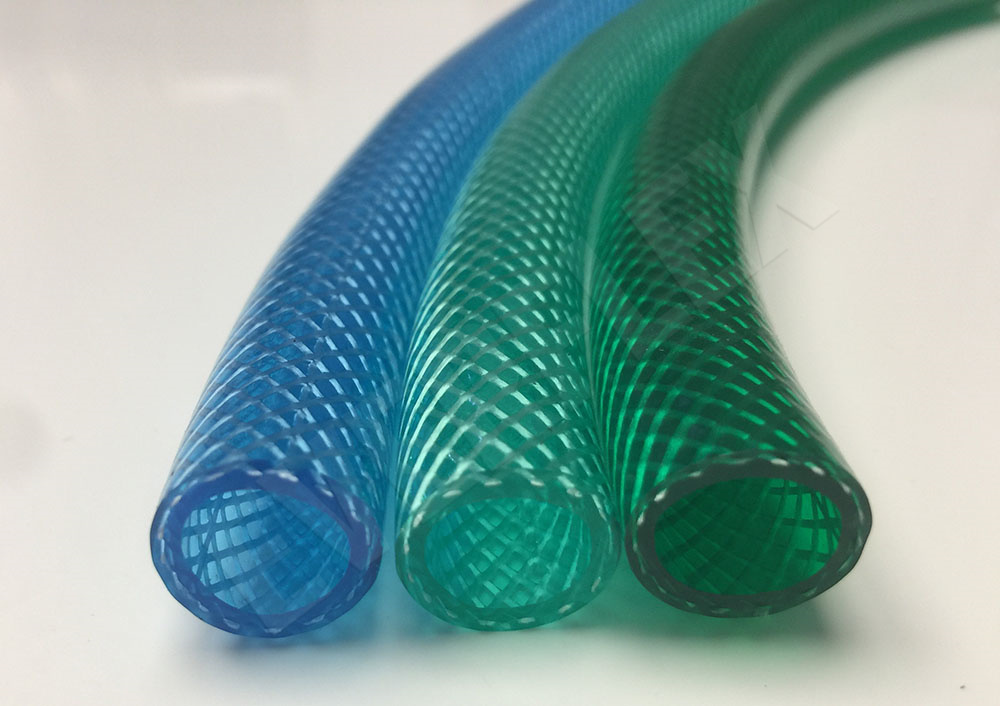

First, we need to know the features of deionized water. It contains very low concentrations of ions, which gives it a high electrical conductivity. Therefore, you should consider the corrosion resistance of the material. In general, stainless steel, PTFE and PE have good corrosion resistance. They are ideal materials for deionized water delivery hose.

Secondly, the inner diameter and length of the delivery hose are also factors to consider. You should select he inner diameter based on the flow rate. Then determine the length based on the conveying distance. Pipes that are too long may increase pressure loss and affect water delivery efficiency. In addition, you should also consider the bending radius of the delivery hose. Because a small one may cause damage to the pipe and affect its service life.

In addition, it is an important step to prevent pollution. Therefore, the sealing and connection method of the delivery hose are very important. Good sealing can prevent external pollutants from entering and ensure water purity. While the connection method should be easy to disassemble and repair. Then it will be easy to clean and replace.

In practical usage, there are some cases that can provide us with reference. For example, deionized water delivery systems in lab often use stainless steel pipe and fitting. It not only ensures corrosion resistance, but also facilitates daily maintenance. For another example, some semiconductor companies use PTFE pipe to transport high-purity deionized water. Its excellent corrosion resistance and high purity meet production needs.