Static electricity is around us. Especially in autumn and winter, we often see lightning flashing on clothes. Similarly, static electricity also exists in industrial production. The rapid movement of materials is a way to generate static electricity. Moreover, production accidents caused by static electricity have occurred both at home and abroad.

There are two kinds of hose that prevents static electricity during use.

The PU static conductive hose is made of a conductive agent mixed with polyurethane raw materials. The walls of the hoses have static conductive properties. This static conductive hose has properties similar to stainless steel hose. Its tube wall can conduct static electricity. This can prevent material clogging and static accidents caused by static electricity.

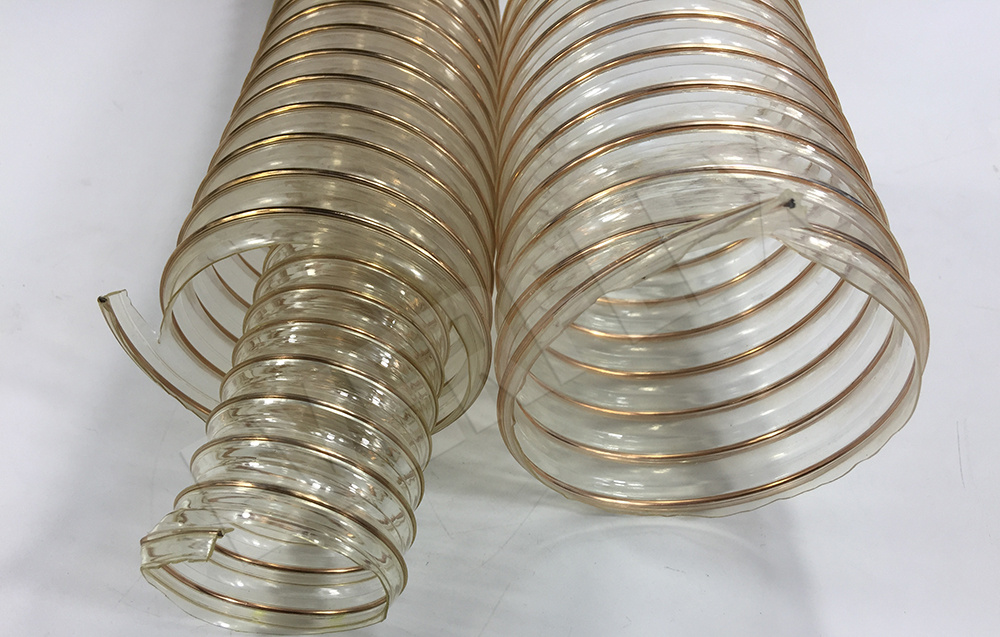

Another anti-static hose is to sandwich a layer of copper wire in the middle of the pipe wall. Since copper wire is a good conductor, it can quickly and effectively conduct static electricity. Thus this plays an antistatic role. When conveying some wear-resistant materials, their friction will cause the separation of positive and negative charges. This is electrostatic ions. Since the pipe wall is insulated, the static ions generated cannot be removed in time. Therefore, the accumulation of much static ions will generate positive and negative charges. This will hinder the transportation of materials. It is necessary to guide the static ions at both ends of the hose to the ground. At this time, the copper wire on the inner wall can quickly neutralize the ions through the stainless steel. This can ensure the normal transportation and circulation in the tube wall. Clamp copper wire anti-static hose is a kind of electrostatic conveying hose commonly used in industry.

The PU hose produced by Everflex has won the trust and recognition of consumer. Good quality and fast and timely service are the two major backers for our survival in the market.