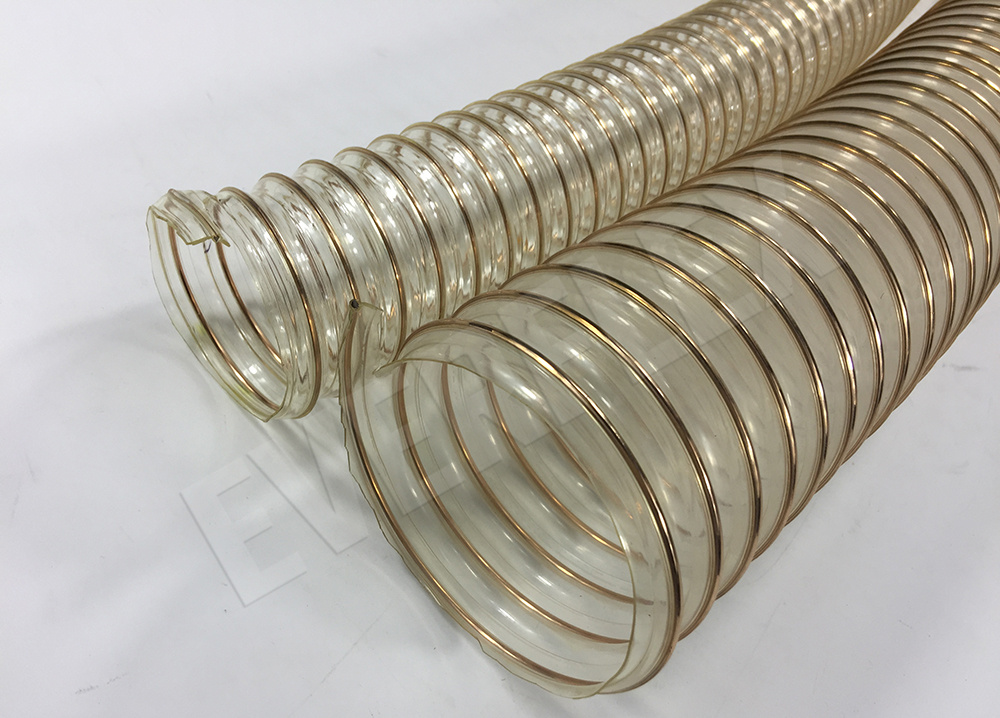

In the production process of PU steel wire pipe, you should make the final demould smooth. Besides, you should reduce the defective products due to product damage. For such purpose you have to use softeners. Thus let’s talk about the routine use of lubricants below. Types and some principles of work, in order to you can learn more about it

Types of common softeners

There are many softeners used for PU steel wire pipe. While the most common ones is paraffin wax. Due to the influence of price factors, paraffin wax is the most used. Next, we will introduce paraffin wax in detail. Synthetic paraffin wax with high melting point can slow down plasticization. But it is hard to make sure the quantity. For fine tuning formula, low molecular weight wax is better. Because it is not very compatible with polar plastics. Besides, it can cause clouding. Thus this use is just in opaque formula.

The role of the softener in the demould of the PU steel wire pipe

There are many benefits of a release agent for PU steel wire hose. First, it avoids the irregular surface of PU steel wire hose. Then it increases the aesthetic feeling. Second. it also changes the surface property of the PU hose to a certain extent. It can also increase its wear resistance.