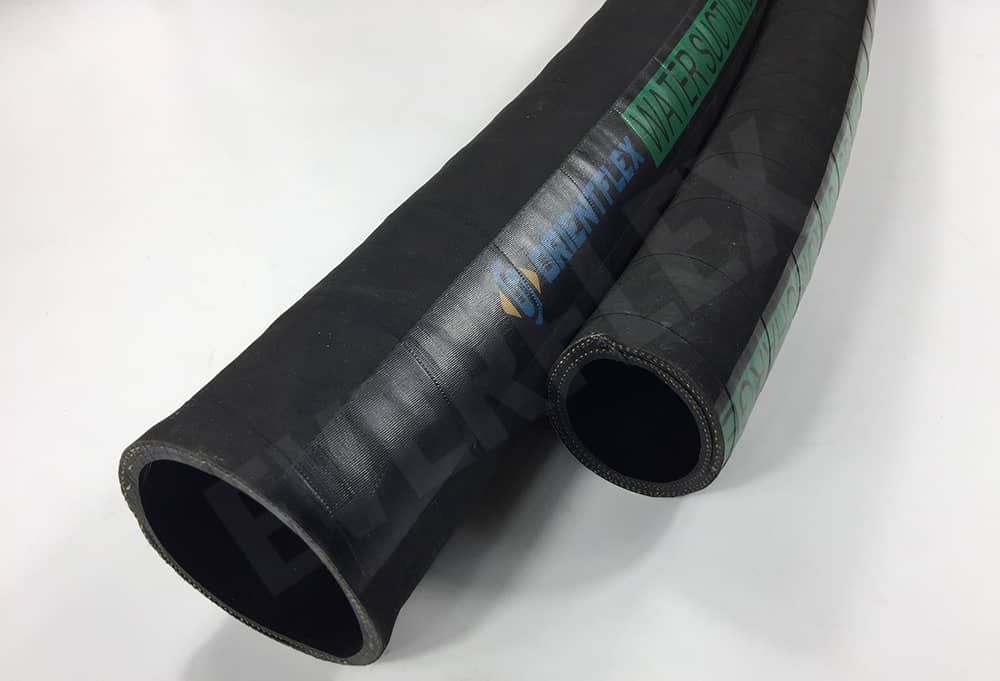

1. Appearance

Different from hard pipes, the biggest feature of rubber hose is its flexibility. Hose designs vary widely depending on operating conditions and performance requirements. Common parameters include size, pressure, weight, length, bending, chemical durability, etc.

2. Industrial grade features

Compared with civilian hoses, the industrial environment is more complex and harsh, and the equipment requirements are higher. Therefore, industrial hoses have strict specifications and standards from design, material selection, production, transportation and even final storage. Industrial hoses come in a variety of sizes with a wider temperature range and better chemical resistance.

3. Industrial application

The application range of industrial hose covers all industrial production and circulation fields, and is widely used in petroleum, chemical, ship, dock, tanker, agriculture, food, beverage, medicine and other industries, as well as hot and cold water, steam, ventilation, refrigeration, fire protection , hydraulic, air and other media, water, fog, mud, sand, iron particles and so on.

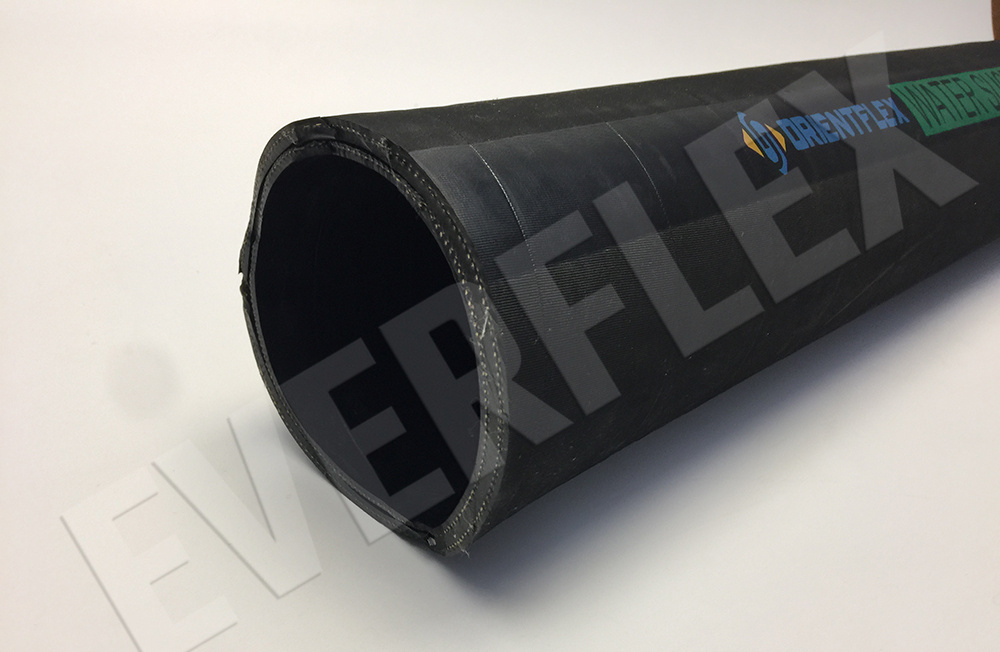

4. Industrial grade process

It is suitable for industrial grade rubber hose, and the medium is water, gas, oil, chemical, etc. It usually consists of an inner layer, an outer layer and a middle layer. The middle layer is usually made of braid and has the effect of enhancing the strength of the hose. In addition, there is an ordinary embedded line between the inner and outer rubber, which is suitable for vacuum negative pressure operation. There are also conductive wires that can be used to inhibit sparks in work environments, such as fuel.