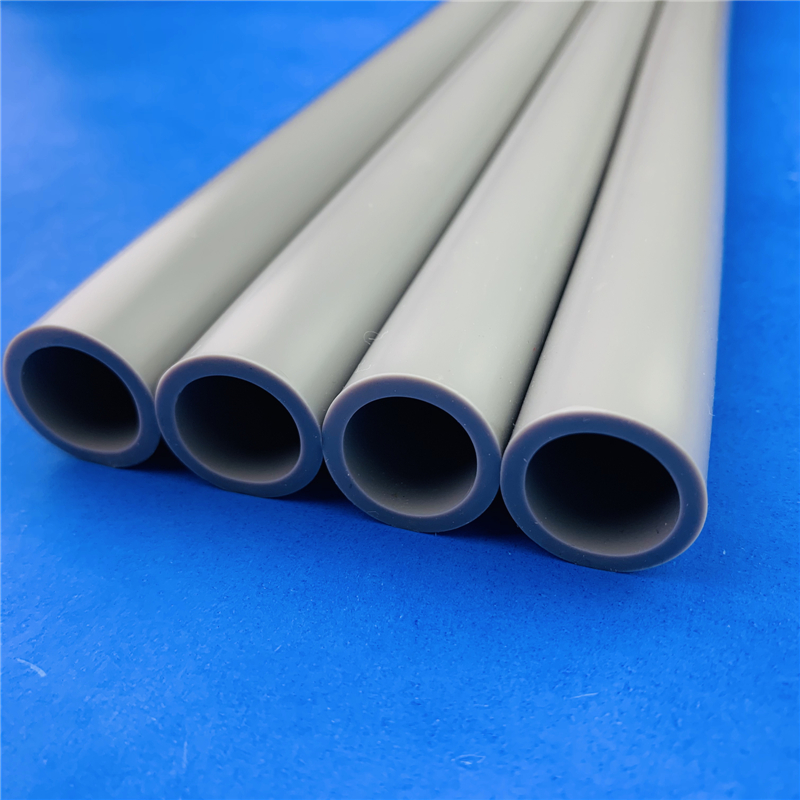

The difference can start from the shape, application field, and production direction. The silicone tube between 15 to 40 meters in length of the extruded body needs to be cured from high temperature and sulfurized from the extrusion input to the mold opening. After passing through the length of more than 15 meters The vulcanization of the drying tunnel is re-sulfurized. Theoretically speaking, the silicone tube of the extrusion process is infinitely long without stopping at the inlet. The solid-liquid injection process uses liquid glue production (similar to glues). The production method is a bit like plastic injection. The liquid glue is injected into the mold after high temperature sulfurization and then demoulded. The solid-liquid injection process has a rich product structure. Variations can be all shapes and results are possible, and the product is produced by liquid glue, so its hardness will be much lower than the silicone tube extrusion process, that is, the solid liquid injection process can reach ≤30 °, and Silicone tube extrusion process does not meet this requirement. In terms of appearance, solid liquid injection products are very soft and very comfortable.

The differences between the silicone tube extrusion process and solid-liquid injection applications are as follows:

1.Solid and liquid injection of the power communication industry: The power industry is one of the most important fields of all silicone products. Any product in the classification of silicone products can be used in the power industry. Silicone has good electrical breakdown resistance and insulation characteristics. Whether it is a solid-liquid silicone insulator for a power terminal or a silicone tube extruded electric cold-shrinkable silicone tube, it has good characteristics. The solid-liquid injection is mainly based on irregular and fixed shapes, and the extrusion process products in the power field are based on Regular round tubes are mainly used, but both can withstand some ultra-high voltage characteristics. They are widely used in power transmission lines and terminals. It can be seen that the extrusion process is round tubes in the field of power communication, while injection is irregular. The silicone products are (general insulators with larger volumes will have higher production costs)

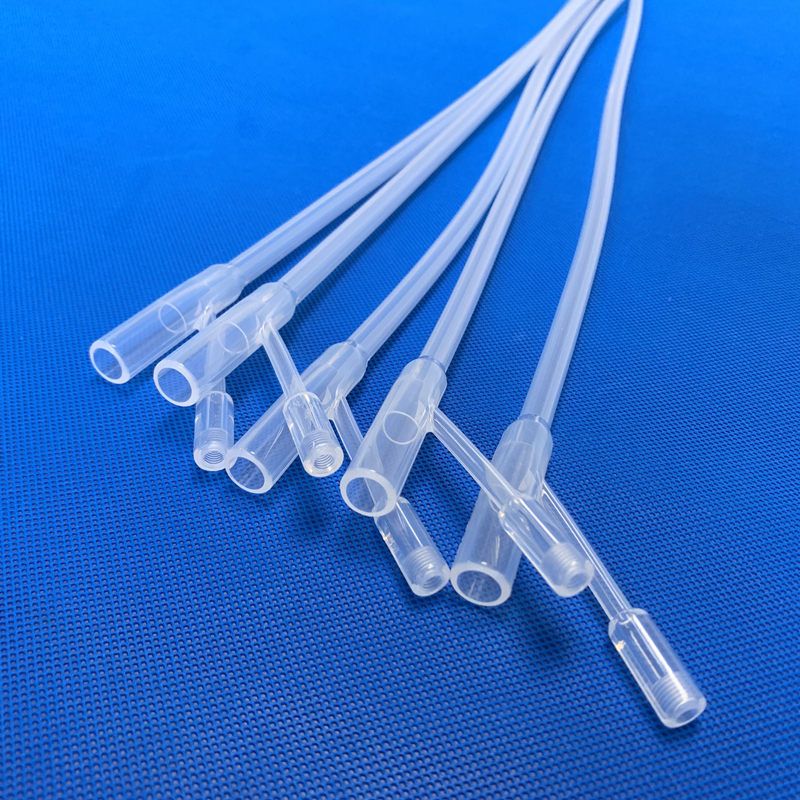

2. Medical field: The silicone tube extrusion process is mainly used in this field to cooperate with the solid-liquid injection process. The extrusion is mainly responsible for the production of the drainage pipe and the triangular split port is produced by the liquid injection molding method. Considered as a whole product, the difference between the two is to make up for each other’s shortcomings. The injection process can mainly produce some irregular pipes. The extrusion process is some regular pipes, but the raw materials used in the liquid process and The cost of all aspects of the equipment will be higher than the cost of extrusion, so it can be produced using a lower cost extrusion process when producing regular pipelines, and because the solid-liquid injection process is more tolerant, it will not exclude extrusion The process has a regular pipeline, which allows the two processes to be flexibly used to reduce their own costs.

On the whole, the solid-liquid injection process from raw materials, auxiliary materials, production and manufacturing processes will have some differences from the silicone tube extrusion process. The liquid silicone used for solid-liquid raw materials is very transparent, while extrusion is mixed with solid The glue is mainly softened by repeated compaction through a compactor, but it is also solid. The solid-liquid injection molding equipment and its name are some of the same made by injection molding machine, because the raw material is liquid and the raw material is filled into the metal mold through the injection nozzle, because the silicone will be formed by crosslinking factor vulcanization molding at a certain temperature. The appearance is determined according to the shape of the customer and the mold. The mold is divided into upper and lower molds while being heated and molded inside the mold for vulcanization. The silicone tube extrusion process is performed by wire cutting or CNC on a flat metal fixture. Processing and cutting into the customer’s required vulcanization are vulcanized in the oven and drying tunnel, and the solid and liquid injection products will be softer after molding (this is related to the liquid raw materials, the general price of the liquid rubber raw materials will be higher quality) Transparency should also be better.) Because the hardness is lower, the product must be soft. Secondly, the transparency is often higher. The hardness of the silicone tube extrusion process is 30 ~ 75 °, which is relatively hard compared to liquid. If the raw material is solid and repeatedly rolled through the compactor, it will become soft but cannot reach the liquid state. There are subtle differences between the application fields of the above two processes from molds to vulcanization to production principles and products.

On the whole, the solid-liquid injection process from raw materials, auxiliary materials, production and manufacturing processes will have some differences from the silicone tube extrusion process. The liquid silicone used for solid-liquid raw materials is very transparent, while extrusion is mixed with solid The glue is mainly softened by repeated compaction through a compactor, but it is also solid. The solid-liquid injection molding equipment and its name are some of the same made by injection molding machine, because the raw material is liquid and the raw material is filled into the metal mold through the injection nozzle, because the silicone will be formed by crosslinking factor vulcanization molding at a certain temperature. The appearance is determined according to the shape of the customer and the mold. The mold is divided into upper and lower molds while being heated and molded inside the mold for vulcanization. The silicone tube extrusion process is performed by wire cutting or CNC on a flat metal fixture. Processing and cutting into the customer’s required vulcanization are vulcanized in the oven and drying tunnel, and the solid and liquid injection products will be softer after molding (this is related to the liquid raw materials, the general price of the liquid rubber raw materials will be higher quality) Transparency should also be better.) Because the hardness is lower, the product must be soft. Secondly, the transparency is often higher. The hardness of the silicone tube extrusion process is 30 ~ 75 °, which is relatively hard compared to liquid. If the raw material is solid and repeatedly rolled through the compactor, it will become soft but cannot reach the liquid state. There are subtle differences between the application fields of the above two processes from molds to vulcanization to production principles and products.