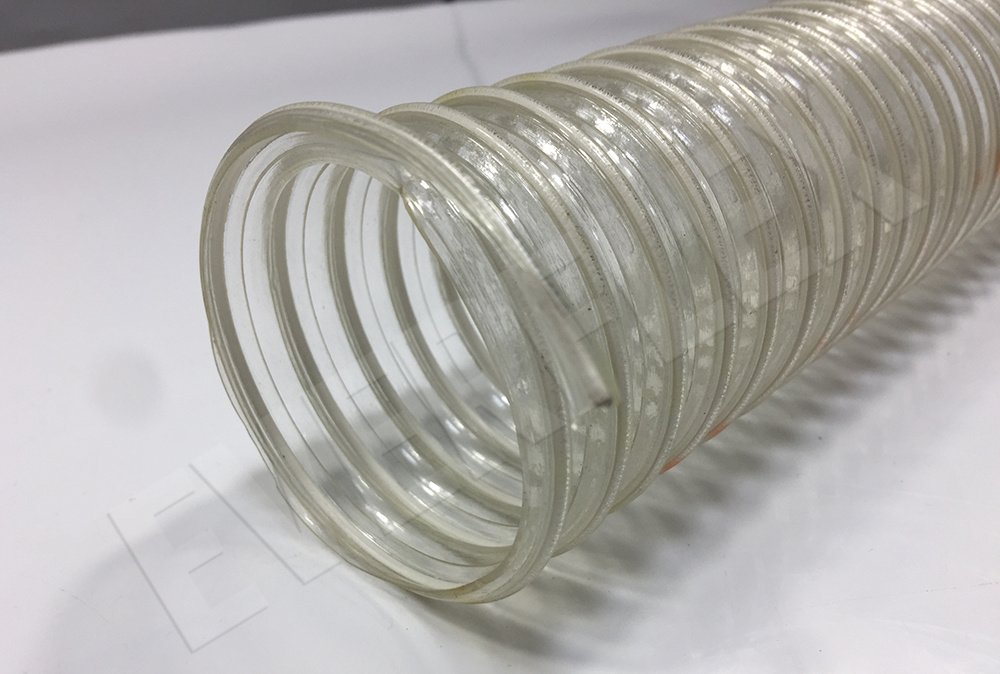

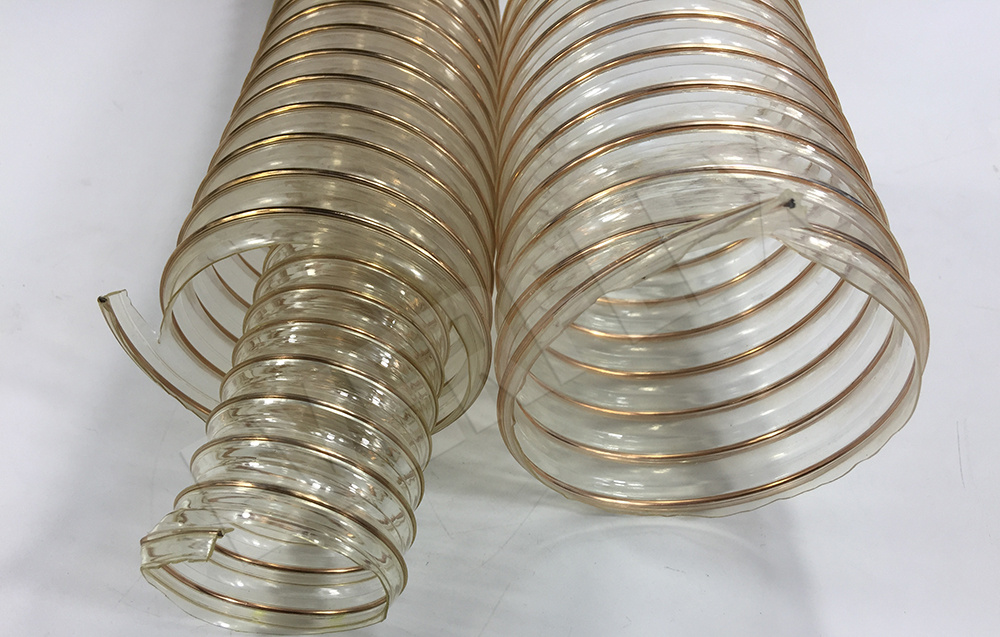

Industrial vacuum industry commonly use two kinds.One is PU steel wire duct hose,the other one is PVC steel wire duct hose.

What are the differences between these two duct hoses?

Different temperature scope

They have different temperature resistance.

Generally,the maximum temperature resistance of PVC steel wire duct hose is 65℃. While the ordinary PU steel wire duct hose can be 90℃. What’s more,the Pu hose can reach 125℃ in short time.

They have different wear resistance

PU steel wire duct hose with more advantage on wear-resistant. In fact,it can be five times as PVC duct hoses.

Therefore, when vacuuming large particles and high wear materials.The life of PVC hose is not durable.

In opposite, the service life of PU wire hose is longer.

They are with different flexibility

When with the same thickness and wire spacing.The PU material wire duct hose will be more flexible.In other words,the PVC material will be relatively hard.

There is a way to make PVC duct hose.

Unless people add more DPO when produce the PVC hose.Although,DPO make hose much more flexible.But flexible PVC hose will not meet the requirements of environmental.Plasticizer take much more proportion.

That is to say it will not suitable for food industry when using too much DPO.There are strict standards.

In conclusion, pu material itself has wear resistance to high and low temperature.

Apart from that,PU hose with tear resistance, anti-aging and anti-static.

Even when the temperature lower to -40℃.Not only the hose will not harden, but also can be use normally.

However,the pvc material hose resistance to low temperature -5℃.

Therefor,pu wire hose is the best choice for ventilation and vacuuming.Consider all walks of life in the cold winter.