Hydraulic pipes are often used in industrial production, but in the long-term use process, it will inevitably encounter hydraulic pipe bursts. As a professional hydraulic pipe manufacturer, I will explain to you how to remedy the hydraulic pipe burst.

When a hydraulic pipe burst occurs in the operation, because the explosion pipe is a high pressure in the hydraulic pipe, in order to avoid excessive loss of hydraulic oil, the bucket should be first grounded, then the engine should be shut down to reduce the pressure in the hydraulic system. Reduce oil loss.

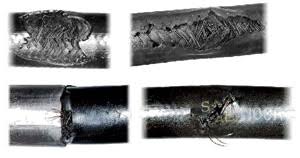

If the construction site conditions are limited and the hydraulic pipe cannot be replaced immediately, certain repair measures can be taken. When the pressure of the hydraulic system is between 25-8.0MPa, the rubber hose can be broken. The specific method is to wipe the hose around the rupture of the hose; apply “anaerobic” glue and “epoxy resin”. One of the glue, “801” glue or “502” glue is wrapped with a tape or cloth strip 4-5 layers (each layer should be glued) to temporarily seal.

In some hydraulic systems of excavators and loaders, the rubber hoses of the same oil circuit have the same specifications but different oil pressures. Most of the broken hoses are hoses with a large oil pressure. Simple splicing or bundling of the ruptured hose; interchangeable use of the large cylinder of the boom cylinder and the tubing of the small cavity (ie, with high pressure, with unbroken tubing, with a pipe that has been damaged but simply glued or bundled Withstand low pressure).

The above method is only used as a temporary emergency remedy. The performance of the hydraulic pipe will be reduced. Therefore, once the hydraulic pipe bursts, the new hydraulic pipe should be replaced and the hydraulic oil should be replenished as soon as possible.