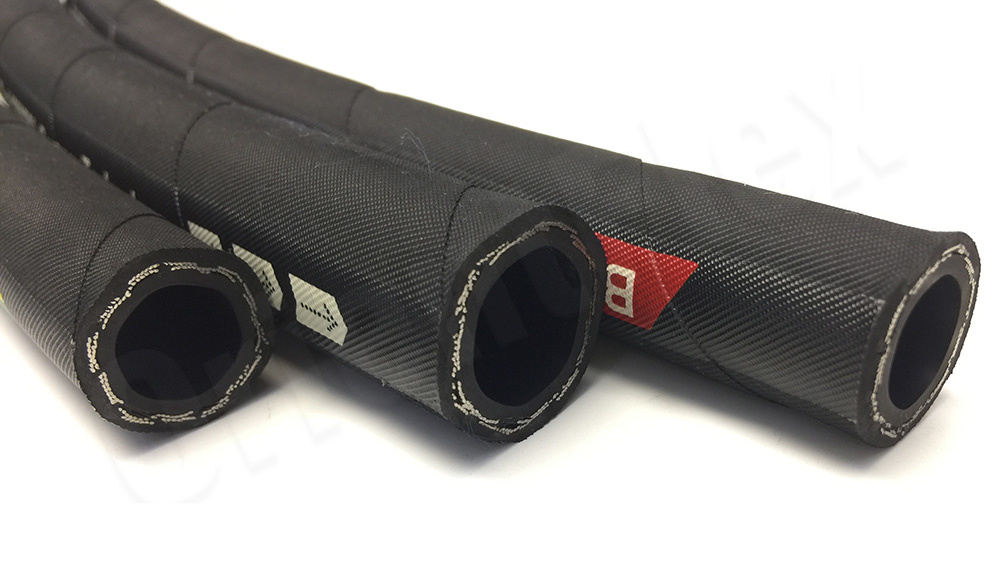

With the development of industry, hydraulic hose is more and more used. While we can say it almost serves in any industries. For such high pressure hose, people always concerns if it is safe and reliable. Therefore, there will be strict tests after the production of the hose. Then next let me show you some tests to the high pressure rubber hose.

Hydraulic hose pressure resistance test

This is to check if the hose is qualified for pressure resistance. While it’s to check if there is any leakage in the pipe body. Then, check if the components are damaged. Those are to make sure if the safety of the high pressure resistant hose is good.

Air tightness test

You should test high pressure rubber hose for air tightness. For such purpose, you can use dry clean air or other protective gas as the test medium. Then fill the gas into the hose and check if there was any leakages.

Uniformity test

Check if the quality of the high pressure hose is uniform. Besides, test if there are irregularities such as colloid adhesion. Any of them can indicate that the hose is not good in quality.

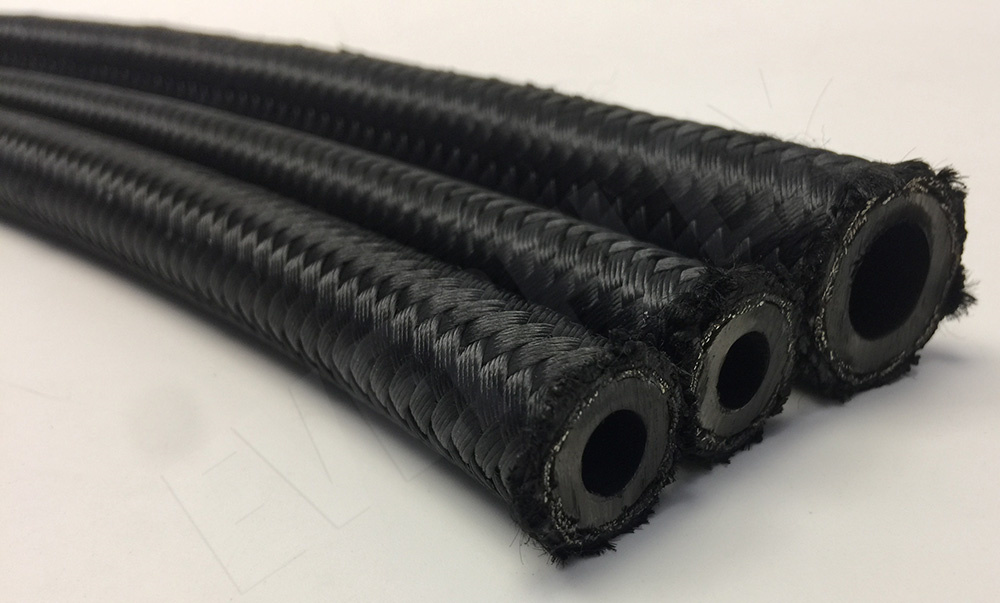

Flexibility test

Bend the high pressure hose properly to see if it has a certain degree of toughness. If it is not flexible, it will not crack because of the over bending. Then it will affect the normal use.

Above are the four tests for hydraulic hose. However, there are many other tests like temp resistance test and ozone resistance test. Only past these test can a hydraulic hose be put on market.