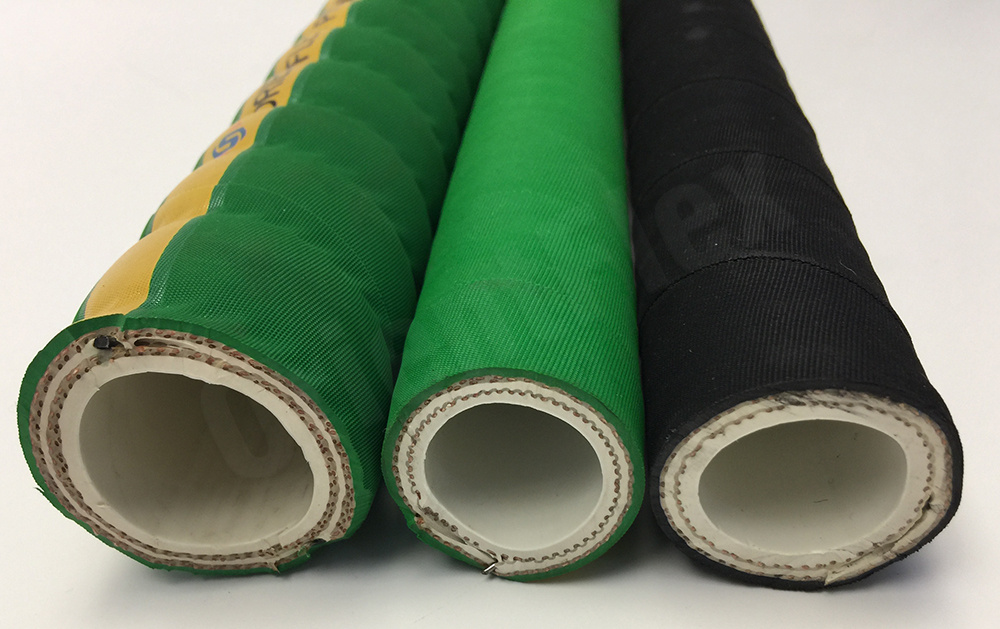

UPE hose, also known as ultra-high molecular weight polyethylene tube. It is a hose made of UHMWPE as raw material. UPE hose is usually composed of UPE inner layer, fiber reinforcement layer and wear resistant rubber layer. UHMWPE is an engineering plastic with excellent mechanical properties and wear resistance. Therefore, it is known as the “steel in plastic”. Its molecular weight is as high as 1 million to 5 million, which is much higher than ordinary plastics. Therefore, it has extremely high wear, tensile and impact resistance.

UPE hose has great wear resistance, mainly including the following aspects:

High molecular weight

UPE material has a high molecular weight and a long molecular chain structure. This gives it good wear resistance. Therefore, it can withstand high friction and impact. The wear resistance of UPE hose is 4-7 times that of ordinary steel pipes and about 10 times that of PE pipes. In a wear environment, UPE hose can still maintain good performance.

Moderate hardness and softness

UPE material has high hardness and strength, which can effectively resist external wear and scratches. At the same time, it has a certain elasticity. It can restore to its original state after being stressed, delaying the occurrence of wear.

Low friction coefficient

UPE material has a low friction coefficient. Therefore, it can reduce friction loss when in contact with other materials, giving it a longer service life.

Chemical corrosion resistance

UPE material has good chemical corrosion resistance. It can be used for a long time in harsh environments such as acid and alkali without being corroded. Thereby protecting the integrity and wear resistance of the material surface.