Automobile engine braking is to use the friction resistance of the engine when it is running to achieve deceleration through the interaction between the transmission gear and the tire. As an auxiliary means of driving braking, it is used in combination with conventional braking on long downhill slopes. This can effectively improve braking efficiency, reduce overheating of the braking system, and ensure driving safety.

As the core component of the car, the engine not only provides power acceleration, but also helps to park stably. The realization of all these functions is inseparable from the synergy of engine braking and starting.

Engine braking, in simple terms, is to use the resistance of the engine to control the vehicle speed without stepping on the accelerator. When the vehicle is coasting with gear, the wheels react to the engine through the transmission system, generating resistance and reducing the speed. The higher the gear, the less the engine affects the speed. Conversely, the lower the gear, the greater the impact.

Taking the actual scenario as an example, when the vehicle is driving at a speed of 60km/h, if the accelerator is released but the gear is not changed, the vehicle will enter the coasting state with gear. The reduction in vehicle speed at this time is due to the effect of engine braking. At this time, the engine does not drive the wheels through the gearbox, but the wheels react to the engine through the gearbox to keep the engine at a high speed.

When driving on a long downhill section, choosing engine braking can effectively reduce the use of brakes. This can avoid performance degradation or even failure caused by overheating of the brakes. Due to the different transmission ratios of different gears, the engine braking effect is better in low gears. Therefore, when going downhill, you should choose the appropriate gear for coasting according to the slope and the expected driving speed.

As a driving term, engine braking can be understood as relying on the drive of the transmission to make the vehicle move forward without consuming fuel. Although this method seems to be eco-friendly, it also has certain risks. Novice drivers should pay special attention to controlling the speed when going downhill to avoid accidents caused by improper speed control.

Three types of brake method

1. Driving brake, this method is used for vehicles in motion. Through the brake pedal, the brake cylinder is controlled to make the drive wheel move from motion to stop;

2. Parking brake, this method is generally used for stopped vehicles. The rear wheel is locked by hand-pulling the lever to prevent the car from sliding backward;

3. Engine brake, this method is generally used for vehicles in high-speed driving. A method of using the traction of the engine to slowly slow down the speed of the car by downshifting.

Introduction

The only force that can brake the car is the external force acting on the car in the opposite direction of the car’s driving direction, and the magnitude of these external forces is random and uncontrollable. Therefore, a series of special devices must be installed on the car to achieve the above functions.

The automobile braking system refers to the braking mechanism that is installed on the car in order to technically ensure the safe driving of the car and increase the average speed of the car. Generally speaking, the automobile braking system includes two independent devices, the driving brake device and the parking brake device. Among them, the driving brake device is operated by the driver’s foot, so it is also called the foot brake device.

The parking brake is operated by the driver’s hand, so it is also called a hand brake.

The function of the service brake is to slow down the car in motion or stop it in the shortest distance. The function of the parking brake is to keep the car parked on various roads. However, in an emergency, the two brakes can be used at the same time to increase the braking effect of the car.

Some special-purpose cars and cars that often travel in mountainous areas. Long-term and frequent braking will cause the service brake to overheat. Therefore, various types of auxiliary brakes are often added to these cars to stabilize the speed when going downhill.

According to the braking energy situation, the braking system can also be divided into three types: human braking system, power braking system and servo braking system. The human braking system uses the driver’s physical strength as the braking energy. The power braking system uses the air pressure or hydraulic pressure converted by the engine power as the braking energy. The servo braking system uses both human power and engine power as braking energy.

In addition, according to the transmission method of braking energy, the braking system can be divided into mechanical, hydraulic, pneumatic and electromagnetic types.

In the automobile braking system, the brake is the component used to generate force to stop the vehicle from moving or moving. The brakes used in automobiles are all friction brakes. That is, the braking torque that stops the movement of the car comes from the friction between the fixed element and the rotating working surface.

Do all four wheels brake together when the car brakes?

Generally speaking, when the car steps on the brake pedal, three different situations will occur. That is, the front wheel locks and skids first, the rear wheel locks and skids first, and the front and rear wheels lock and skid. At the same time, in these three situations, the braking is only different in the distribution of braking force, not the first brake. It is the ability of the four wheels to brake at the same time. Many friends may think that the distance from the brake line of a passenger car to the front wheel is short and the distance to the rear wheel is long. Therefore, it is mistakenly believed that the braking of the front and rear wheels should appear in sequence when braking. In fact, this view is wrong.

Take the current passenger car as an example, almost all of them use hydraulic brakes. So no matter the layout and length of the brake line, the brake oil is added to the brake line (if there are bubbles). So no matter how big the brake line is, the difference between the length of the front and rear brake pipes is that as long as the brake pedal is pressed, the front and rear brake pipes will generate pressure at the same time.

So the front and rear brakes are applied at the same time, and there is only a difference in the distribution of power. Family cars are mainly hydraulic brake systems. When the brake pedal is pressed, the master brake cylinder is controlled. The brake on the wheel is the brake cylinder, which absorbs brake fluid and transmits braking force through the brake fluid.

Therefore, air will not be released into the brake pipe. Because air can be compressed, the pressure of the brake fluid is used to compress the air during braking, and the braking force cannot be transmitted to the wheel brake. Therefore, after replacing the brake fluid, be sure to pay attention to bleed. And the brake pipe must be protected. If the brake pipe is broken, the corresponding circuit will lose braking force.

Fortunately, now all cars use a dual-circuit brake system. That is, the master cylinder has two pipes to control the two wheels in the diagonal position. For example, one way controls the left front wheel and the right rear wheel, and the other way controls the right front wheel and the left rear wheel. If one of the pipes is broken, there are still two wheels with braking force.

But if both pipes are broken, the brakes will be completely ineffective. The braking system of this car uses hydraulic braking. The fluid fills the entire brake line and is incompressible, which can transmit 100% of the power. When the driver steps on the brake pedal, the brake fluid in the brake system will be pressurized.

The braking system uses Pascal’s law. As long as the fluid in the sealed container applies external pressure and the fluid remains stationary, the pressure at any point in the fluid will produce a change of the same value. The owner steps on the brake pedal and pressurizes the brake fluid. The pressure is applied to the brake caliper piston of each wheel 100% through the brake fluid. Then the piston pushes the brake caliper to compress the brake disc.

The ignition switch is turned on and the ABS control unit starts working. If the driver steps on the brake pedal while the car is driving, the pedal force will be amplified by the vacuum booster and act on the master brake cylinder. The force on each wheel is theoretically equal. However, since the actual force acting on each wheel is different. If the braking force is equal, it will cause insufficient braking force on the front wheel and excessive braking force on the rear wheel. Because under normal circumstances, the car is front-wheel drive. In theory, the braking force is distributed as 60% to the front wheel and 40% to the rear wheel. This ensures the braking stability of the vehicle. For the actual braking force, the friction of the road surface on the wheel must also be considered. For example, as the braking force increases, the braking force of the four wheels increases synchronously. Still moving forward under the influence of inertia. The center of gravity also moves forward. In this case, the load on the front wheel is greater than that on the rear wheel. Therefore, the brake pads of the front wheels are more worn than those of the rear wheels.

So is it feasible to brake only the front wheels or the rear wheels?

Of course not, because no matter how the performance of the car is, the biggest requirement for rigidity is stability. Braking only the front wheels or the rear wheels will inevitably cause the vehicle’s braking force to deviate too much. This will cause the wheels to slip and cause great damage to the chassis.

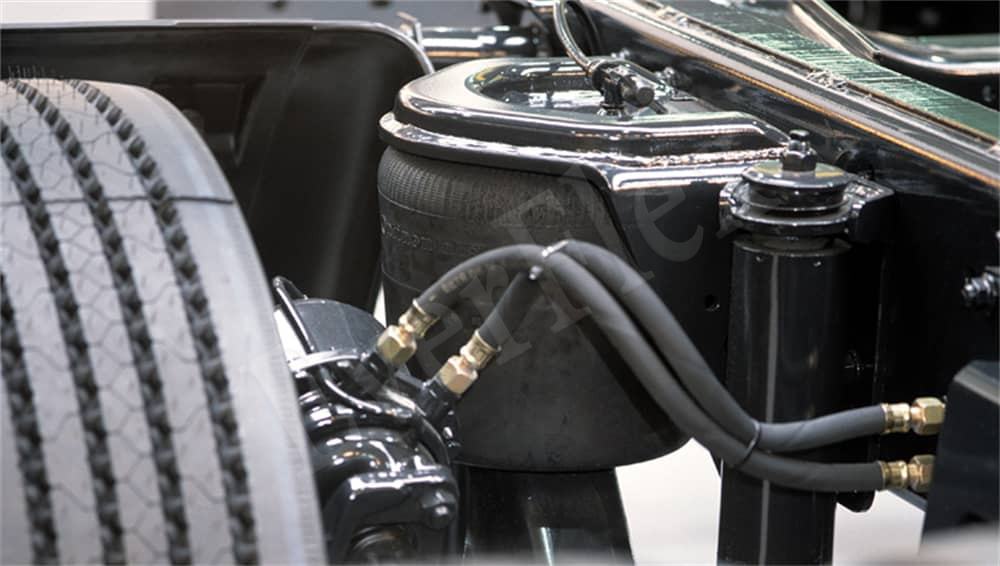

As a part in a brake system, the brake hose concerns the driving safety. In the brake system in a car, the air brake hose SAE J1401 and SAE J1402 plays an important role.

The main functions of air brake hose

Transfer brake fluid

The brake hose connects the brake master cylinder and the brake caliper to transfer the brake fluid pressure, thereby achieving vehicle braking.

Ensure the fluid tightness of the brake system

The brake hose must have excellent sealing performance to prevent brake fluid leakage and ensure the normal operation of the brake system.

Adapt to vehicle movement

The brake hose needs to have good flexibility and tensile strength. To adapt to various movements of the vehicle during driving, turning and braking.

Withstand harsh environments

The brake hose must be able to work normally in harsh environments such as high temperature, low temperature, ozone, etc., and maintain stable braking performance.