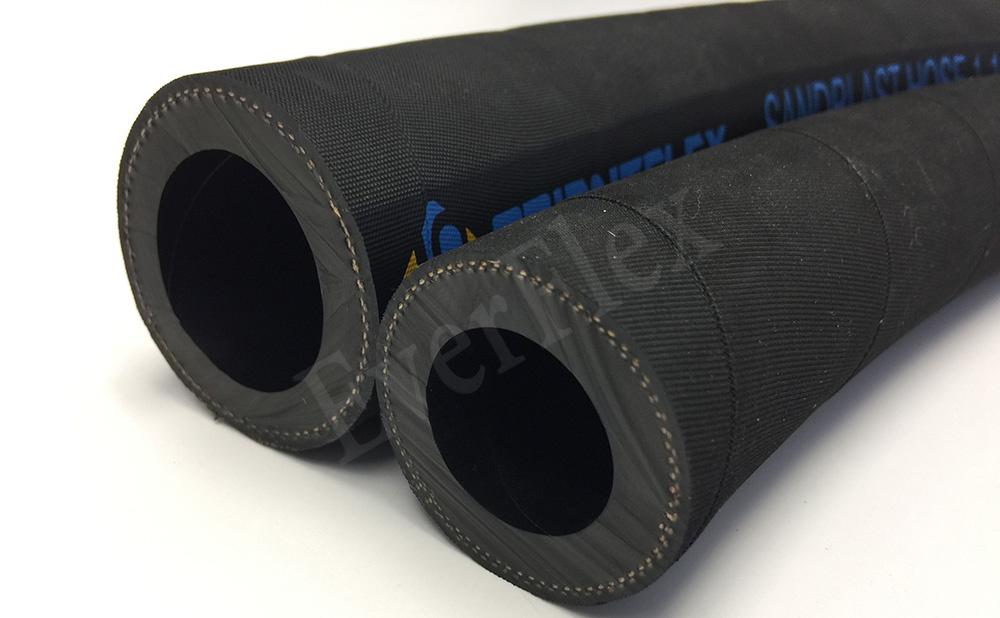

Sandblasting pipe features:

Excellent wear resistance

When can a blast hose be replaced?

Knowing the signs of wear on your sandblasting hose will allow you to replace it when the time is right. Thereby maximizing your productivity and profitability. Early replacement is not cost-effective, and late replacement can affect productivity and safety.

external signs of damage

The easiest way to check for wear is to visually look for signs of damage on the exterior blast hose. Finding cavities, cracks, splits, or material erosion in the outer wall is a reliable sign that the hose needs to be replaced.

Hoses Integrity

Another way to identify a hose is to squeeze it. The blast hose should be squeezed every 20 cm of length. A hose that fits well is difficult to squeeze. If the hose presses down when squeezed, it indicates that the inner wall is corroded due to the flow of abrasive and should be replaced. If there is only one spot that is dented, and it is near one of the ends, you can cut off the frayed section and attach the fitting to the end.

A compromised layout

If the operator bends the hose at a severe radius, the hose may wear out prematurely. This is very unsafe. Because the wear point is close to the operator. To prevent dangerous wear points, operators should stretch the hose to the widest possible radius (nearly straight) when blasting. This involves the entire hose length from the blast tank to the operator.