Composite hose is a special package container and plays an important part. It is the cylindrical hose made from flexible material. One side is seal while there is a nozzle on the other side. Then the substance extrude out with pressure.

However, the definition of composite hose is more wide. Meanwhile, the composite hose is no longer only the package. In fact, it becomes an great material for many applications.

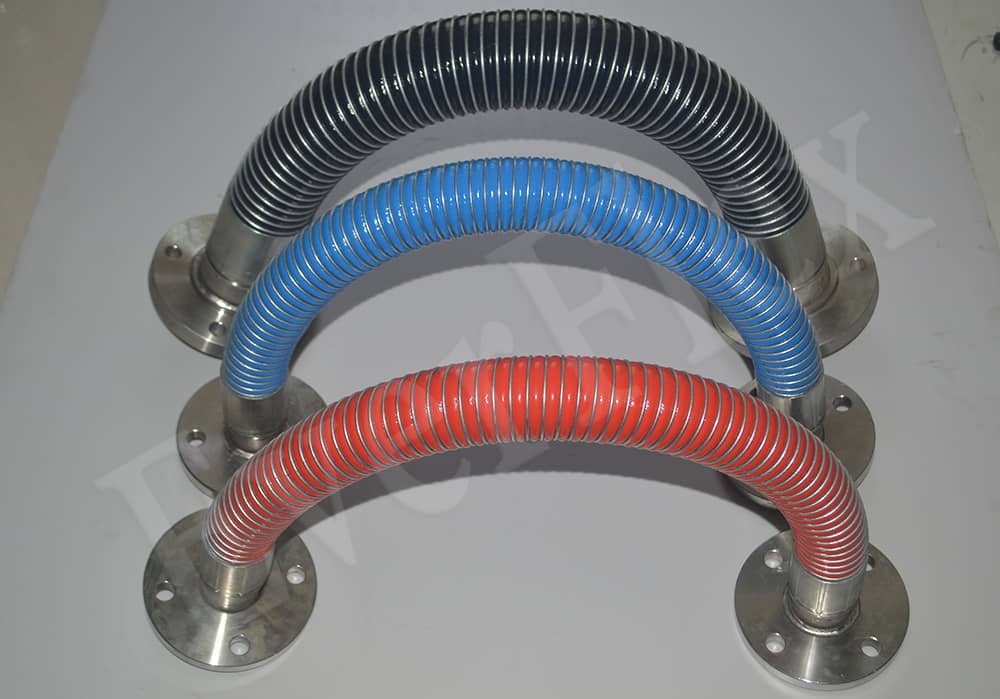

Structure of composite hose

Generally, composite hose is made from layers of compound. While the reinforcement is synthetic. Besides, there are two layers of steel wire braid on the internal and external layer. The special structure combines the capacities of different materials. Thus it’s flexible, light in weight and corrosion resistance. Besides, it can work at low and high temperature. Therefore, composite hose is more and more used in all the industries.

Then how to classify composite hose?

Based on different usage, the composite hose can be divided into the following types.

Oil resistant composite hose

It’s mainly to transfer gas or liquid fuels such as gasoline, diesel and crude oil.

Chemical transfer composite hose

Such hose is to transfer corrosive chemical liquid and gas. Because it has great chemical resistance.

Auto composite hose

The main usage is oil tank truck. It’s flexible, thus suitable for use with frequent bend. Besides, it has much longer lifespan.

Dock oil hose

It belongs to heavy duty composite hose and mainly for marines on the dock. Such hose has strong structure and excellent chemical resistance.

Paint hose

Paint hose is to spray paint products. Because it has great solvent and abrasion resistance.

Temperature resistant hose can transfer low temperature mediums like LPG and LNG. Besides, it can also transfer high temperature mediums such as hot oil.

Above is the classification of composite hose. If you have any question or inquiry, please fell free to contact EverFlex.