Is Teflon tube different from stainless steel metal hose?

Teflon and metal hose are often mistaken for the same material because of there are many features in common, such as: high temperature, corrosion resistance, wear resistance. And in the electrical, chemical, mechanical, metal surface treatment, pharmaceutical, medical, food, metallurgical smelting and other industries are widely used as high and low temperature resistance, corrosion-resistant materials, insulation materials, anti-stick coating, making it irreplaceable product. After all, material is not the same, so there are still many different characteristics.

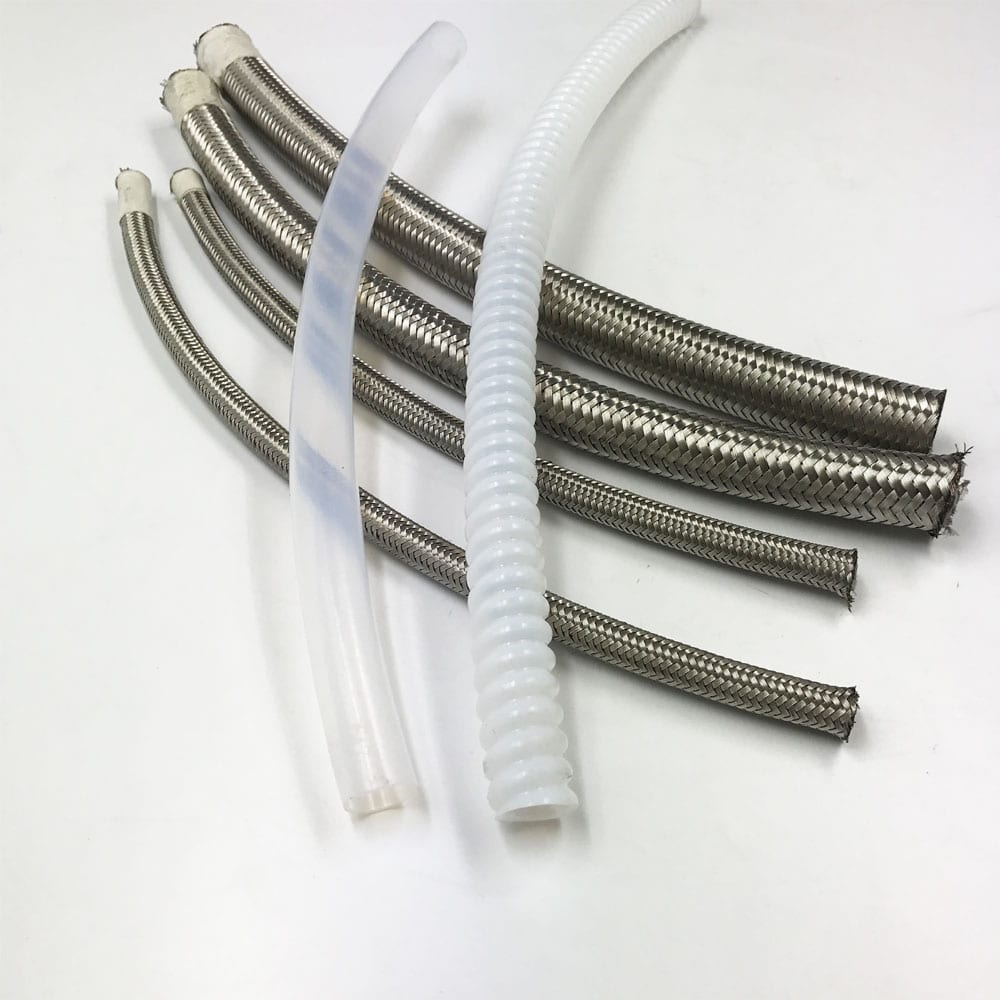

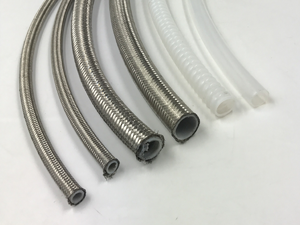

Teflon hose

1, high temperature: Teflon tube has a good high temperature and low temperature characteristics, the shortest time the maximum temperature can reach 300 ℃, generally between 240 ℃ ~ 260 ℃ can be used continuously, it can work at the freezing temperature Not brittle, do not melt at high temperatures.

2, sliding: Teflon coating has a lower coefficient of friction. The friction coefficient changes when the load is sliding, but the value is only between 0.05 and 0.15.

3, corrosion resistance: with acid and alkali resistance, anti-organic solvent characteristics, almost insoluble in all solvents, parts can be protected by any chemical corrosion.

4, wear resistance: with excellent wear resistance. In a certain load, with wear and non-adhesion of the dual advantages.

Stainless steel metal hose, widely used in wood, textile, construction, medicine, food, tobacco, transportation, aviation, aerospace, petroleum, chemical, metallurgy, power, paper and other industries.

1, wear resistance: metal hose with anti-rat bite, to prevent the internal wiring is worn.

2, flexibility: bending radius is small, good flexibility.

3, resistant to bending: tensile properties, anti-lateral pressure strong.

4, joint connection and more, easy to connect with the instrument, the structure is generally divided into spiral, flange and fast three categories.