Fuel Dispenser hose is designed to dispense and transfer gasoline and other petroleum based fuels. The CPE and chloroprene covers are cut, abrasion and ozone resistant and will not damage the finish of a vehicle. Thus the oil hose is really durable.

In the work, there will be a breaking valve on the fuel dispenser hose. While the fuction of the valve is to avoid the high tensile strength breaking the fuel dispenser. Because there is the risk that the hose still on the car after the refuel work. Then the car goes and drag the hose. So that it may hurt the hose and the dispenser. Besides, you should regularly check the valve and see if it was in work status. Once there was any problem, stop the refuel work and change a new one.

Fuel Dispenser Hose Structure:

Tube: Nitrile rubber, smooth

Reinforcement: steel wire braid

Cover: Nitrile rubber, black, green, red, blue or yellow

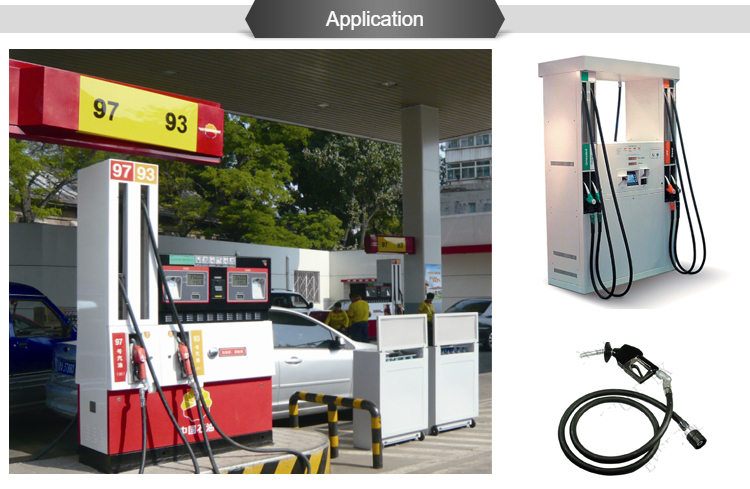

Application:

The dispenser hose is designed for general refueling equipment to convey aviation kerosene, gasoline, diesel oil and other mineral oils.

Gas Dispenser Hose Features:

Designed for fuel up to 50% aromatic content

Weather and ozone resistant cover

C/W coupling SHF

Temperature: -40°C to +121°C (-104°F to +250°F)