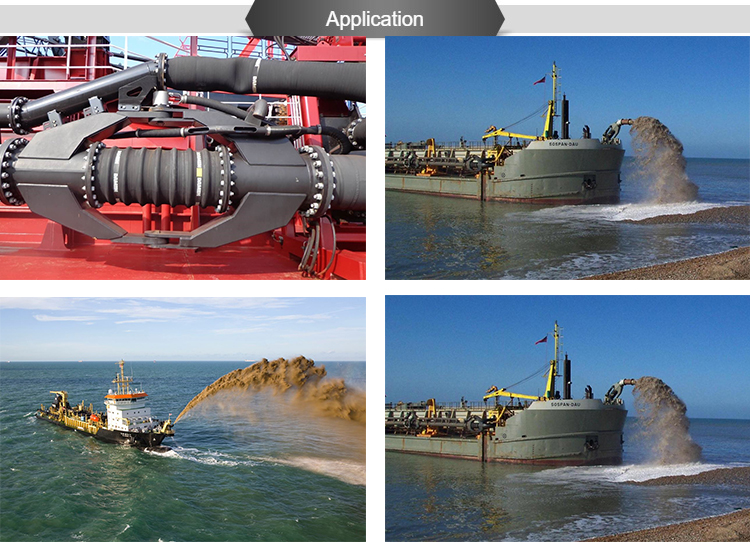

Suction Dredging Hose Application:

Suction dredging hose is designed for silt conveyance dredging operations. The flexible and easily installed dredging hose is abrasion and kink resistant because of the synthetic materials combined with the helix steel reinforcement wire. The smooth interior of the hoses helps prevent clogs and avoids damage from the abrasive materials passing through.

The mud discharge dredging hose is a mud discharge hose configured for a suction dredger or a suction dredger. Generally made of cast steel or steel plate, each section is 4-7m long, and the wall thickness is related to the pipe diameter and pressure, generally 5-10mm. The discharge pipe connected from the stern of the dredger is supported by buoys and floats on the water. Each set consists of two round, oval, rectangular or boat-shaped buoys. Each section of the mud dredging hose is connected by a rubber sleeve. The iron card was clamped. The mud discharge pipes on the shore are mostly connected by flange bolts, and equipped with elbows, short pipes and branch pipes, which can be sent to the mud throwing area.

On the shore, the dredging rubber hose arranged in the nearshore waters is erected on the mud discharge pipe frame. The joints between the floating pipe and the shore pipe should meet the requirements of expansion and swing, and are usually composed of spherical or rubber joints, telescopic pipes, short pipes, etc.

Temperature: -25℃ to +80℃(-13℉ to +176℉)

Tube: Abrasive resistant synthetic rubber with high strength breaker plies and coated with a high grade synthetic rubber interior surface.

Reinforcement: High tensile strength fabrics with a steel inner structure. Fully embedded steel wire coils are incorporated to achieve kink, crush and local load resistance.

Cover: Synthetic rubber, resistant to abrasion, weathering, sea water and oil exposure. The cover, which incorporates reinforcing breaker plies is black with a bright orange spiral stripe or coated in tough bright orange polyurethane.