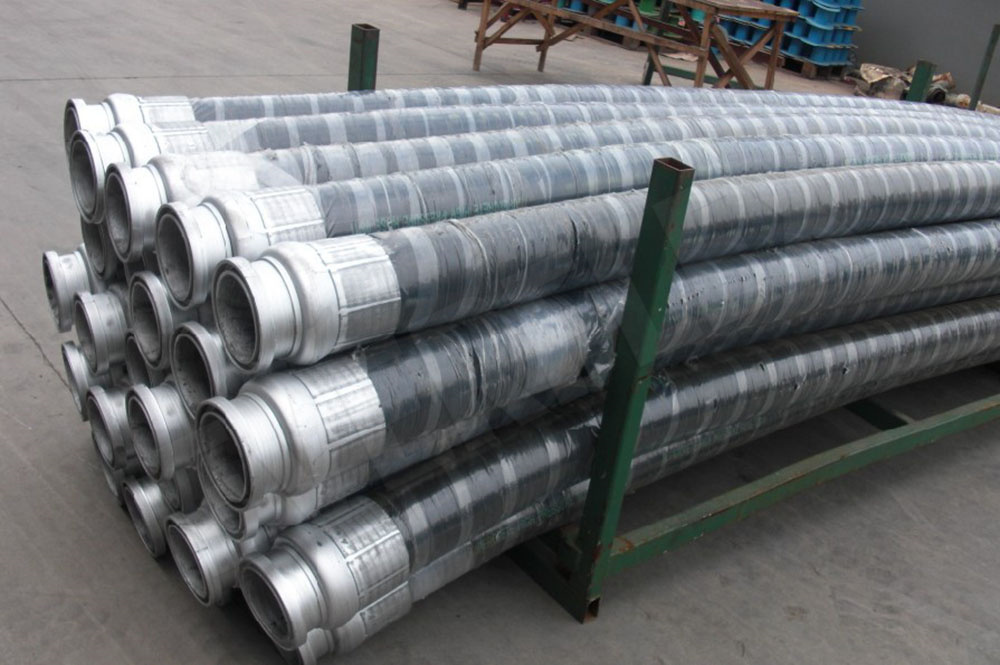

The concrete pump hose is an important accessory on the concrete pump. While it is to deliver concrete. However, concrete is abrasive. Thus when the concrete reaches a certain amount, the hose will wear out. Then you have to replace a new hose. However, if you maintain your concrete hose well, it can prolong the service life. Then how to maintain the concrete rubber hose?

Everflex offers you some tips to maintain concrete pump hose

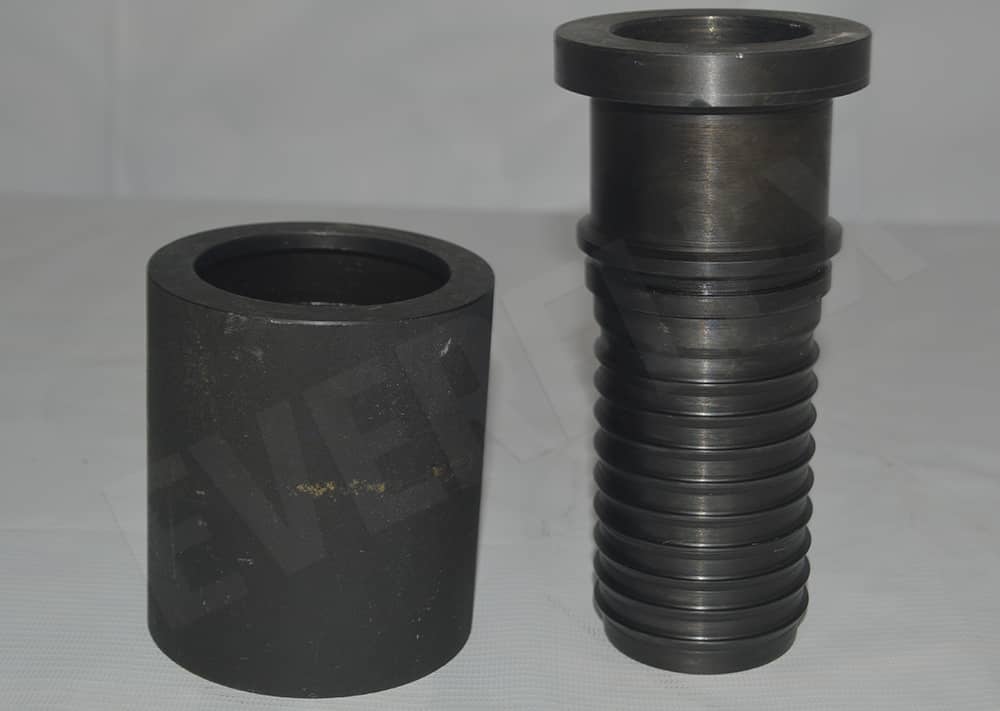

First, before purchasing a concrete pump pipe, make sure the specs. While these specs include the wall thickness, the weight and the reinforce layer. Because they performs differently in dealing concrete.

Second, regularly check if the thickness of the concrete pump pipe has changed. If the wall thickness becomes thinner, it means serious wear of the rubber pipe.

Third, when the amount of concrete pump pipe reaches half, loosen the pipe clamp and turn it to the concrete pump pipe. Because if the pump pipe does not rotate, uneven stress will occur. Then it cause the pump pipe fail earlier.

Fourth, regularly check the flange joint of the pump pipe to see if it explode. If you find the problem, deal with it in time. Otherwise it will cause bigger problems.

Last, after each use, clean the concrete pump hose. And never let the concrete reserve in.

Above are the 5 tips to maintain your concrete pumping hose. If you want to learn more, please just consult Orientflex. We are an expert in fluid solution. Besides standard concrete hose, we can offer you customized hose. What’s more, we offer you unique one-stop service. While that means you can get the cost-effective hose with concrete hose clamps. Then you can save much time to find a hose fitting supplier. Of course, factory hose with factory direct price will help you save budget.