Ink delivery mainly involves the transmission and distribution process of ink. The purpose is to improve the fluidity of ink, make the printed ink layer more uniform and delicate, and thus obtain high-quality printing effects. The ink delivery system usually consists of multiple rollers, between which the ink is transferred and distributed. It undergoes shearing, squeezing, stretching and separation, thereby improving its fluidity.

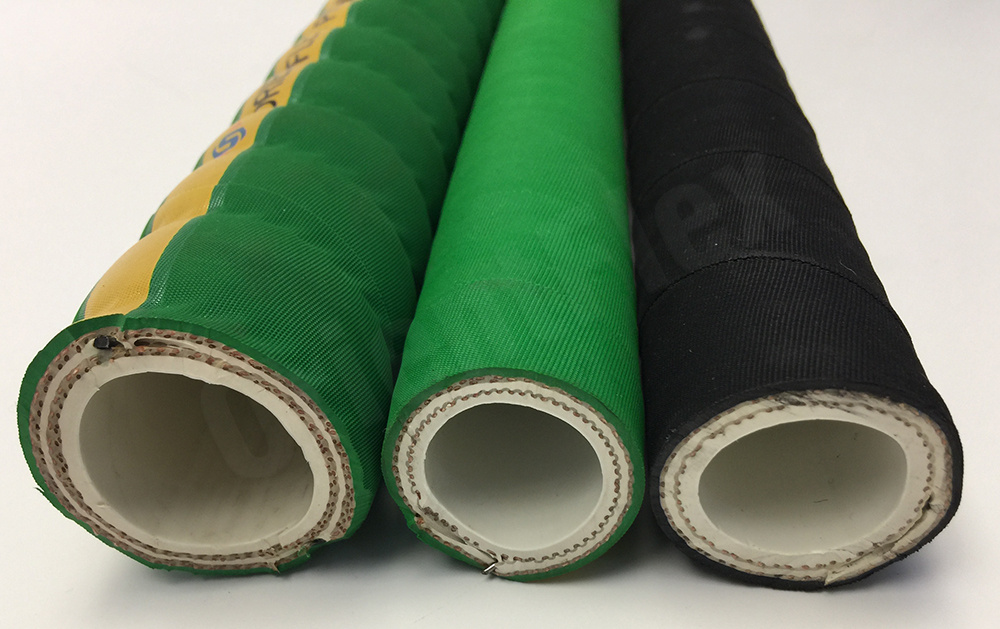

Industrial hoses play a vital role in the ink delivery process. Ink is a special liquid, and its delivery requires special pipes to ensure smooth, safe and efficient delivery. Hoses are the ideal choice to meet these needs.

First, the excellent flexibility and bendability of the hose

This makes it adaptable to various complex delivery routes and layouts. Whether it is straight or curved delivery, the hose can easily cope with it, ensuring that the ink can be smoothly delivered from the starting point to the end point.

Secondly, the hose usually has good chemical stability

Can resist the erosion of chemicals that may be present in the ink. This is crucial to ensure the stability and safety of the ink delivery process.

In addition, the hose also has high pressure resistance and temperature resistance

Can withstand the pressure and temperature changes that may occur during the ink delivery process. This ensures that the hose can maintain stable performance during long-term, high-load ink delivery. And there will be no problems such as rupture or leakage.

In the ink delivery system, the hose is usually used in conjunction with other equipment (such as pumps, meters, etc.) to achieve accurate and efficient delivery of ink. The existence of the hose makes the entire delivery system more flexible and reliable, and can operate stably in various complex environments.