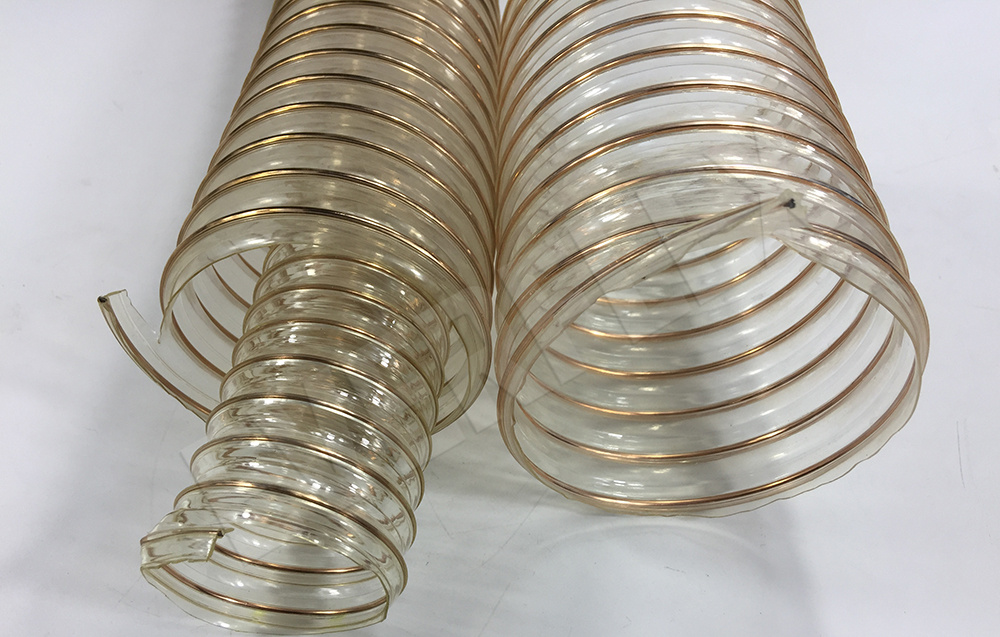

We usually see differences in the transparency of many finished PU steel wire hoses. Some PU pipes are as transparent as glass. However, there are also many hoses that are yellowed or whitish.

So why does PU steel wire hose turn yellow?

First, yellowing of PU steel wire hose is due to antioxidant effect. Nowadays, many PU steel wire hoses mainly choose TDI or MDI as raw materials. This type of substance undergoes complex chemical reactions under the action of light, heat, oxygen, especially UV rays to generate chromophores. The resulting PU steel wire hose is easy to turn yellow. High transparency cannot be maintained for a long time.

Second, the effect of ultraviolet rays can also cause yellowing of PU steel wire hoses. When the finished PU steel wire hose is produced and needs to be left for a period of time. Place in a dry area with low light. Especially avoid direct sunlight.

Solution

Minimize the oxygen content in areas where PU steel wire hoses are produced and stored (can be filled with inert gas). Methods such as adding antioxidants and UV absorbers can also be used to effectively delay the yellowing of PU steel wire hoses. Of course, yellowing does not affect the performance of the PU hose, but only affects the visual experience.

Everflex introduced the top grade quality raw materials to produce PU duct hose. Thus the date of yellowing can be more later. Besides, our hose has a much longer service. If you need high performance flexible hose, contact us now.