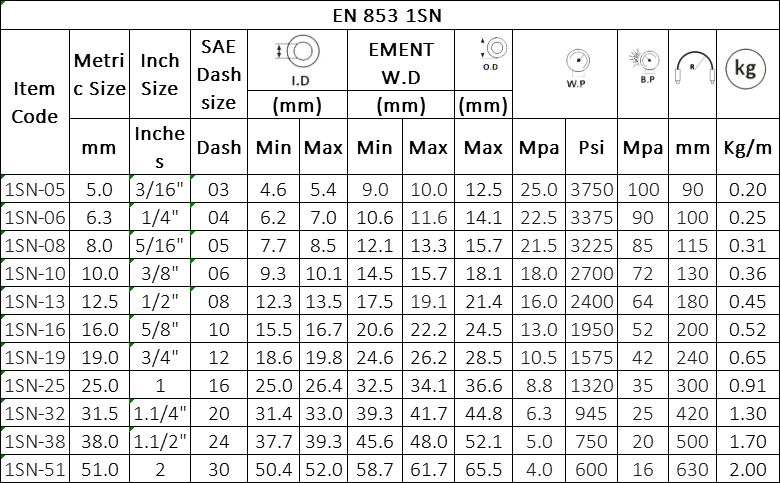

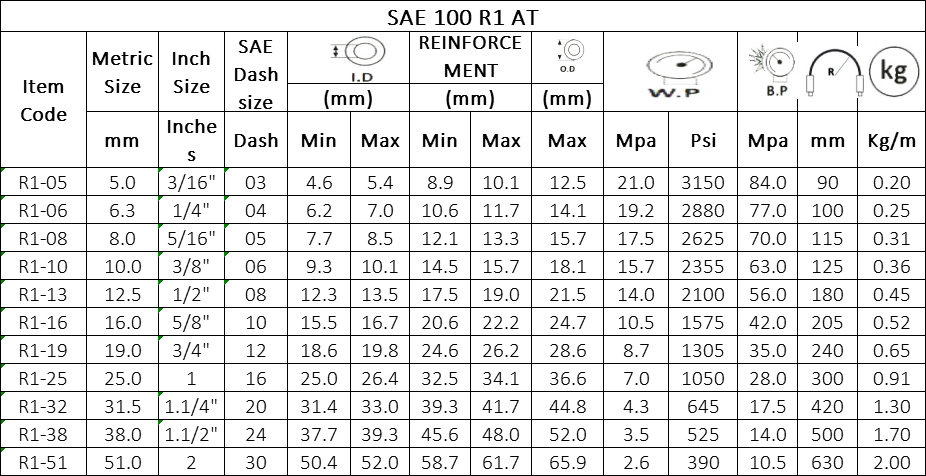

SAE 100 R1 steel wire reinforced hydraulic hose is suitable for medium pressure hydraulic lines. It exceeds the performance requirements of SAE 100 R1 Type AT and EN 853 1SN. It can bear higher working pressure than other rubber hoses thanks to its high tensile braided steel wire reinforce. Hydraulic hose R1 consists of three parts: tube, reinforce and cover. The tube is made from oil resistant rubber, making the hose perform well when deliver oils. The reinforce is one layer of high tensile braided steel wire, making the hose resist high pressure. While the cover is made from high quality rubber, making the hose resistant to abrasion, corrosion, weather, ozone, aging, sunlight and cut. Therefore, it has longer service life.

Hydraulic Hose R1 is Ideal For:

Medium pressure hydraulic lines.

Application Fields: Mine hydraulic support, oilfield extraction machinery, mine/road/construction machinery

Structure:

Tube: Black and oil resistant synthetic rubber

Reinforce: One braid of high-tensile steel wire.

Cover: Black, oil,brasion and weather resistant synthetic rubber.

Temperature Range:

-40℉ to +250℉ (-40℃ to +121℃)

Application :

Hydraulic hose SAE 100R1 / EN 853 1SN can be used for forklift, hydraulic engine, oilfield extraction machinery, mine/road/construction machinery and so on.

Raw Material:

Raw Material:

Importe rubber materials from South Korea,

Importe BELKTA steel wire with high tensile strength 2750Mpa from Belgium.

Good quality materials provide our hydraulic hose steady performance,

Good decentrality and excellent oil resistance.

Factory Workshop:

Our factory introduces advanced technology and equipment to make the best quality hydraulic hose.

Our bunching machine is SEJIN MACHINE from Korea.The advantages of the machine are high accuracy and high consistency. The suspension difference < 70MM, while the international standard is 120MM.

We use Mitsubishi electric control braiding machine to get high accuracy data collection, real-time braiding angle monitoring and correction.

Laboratory:

Our factory has strong quality control team and we set up advanced laboratory.

Before the mass production, we test each batch of raw material

After the production, we test each hose to guarantee a 100% qualification.

Each hose is tested 2 times on working pressure.

We do everything that possible to supply good quality hoses for our customer.

Packing:

After the production, we will pack the hydraulic hose. In general, the packing could be woven bag and plastic film. Special packing is available on your demand.